Product Description

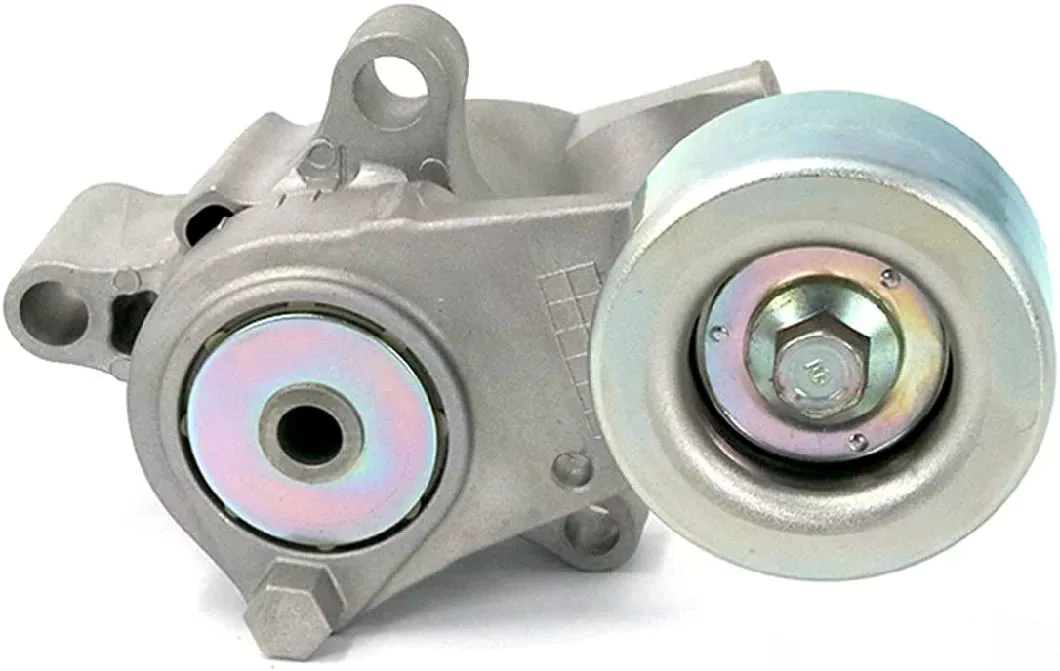

ISX15 QSX15 engine belt tensioner 2891940 369 3682683 3682255

| Part Number | 2891940 369 3682683 3682255 |

| Part Name | belt tensioner |

| Brand Name | OEM |

| Engine Family | QSX15 ISX15 |

| Warranty | 3 Months |

| Packing | Original Customized |

| MOQ | 1 PCS |

| 1 | 1 | 4925884 | Socket Head Cap ScrewSocket Head Cap Screw | ||

| 2 | 3682261 | V Ribbed Belt | 1 | ||

| 3 | 3682229 | Idler Pulley | 1 | ||

| 4 | 315719 |

| Belt Tensioner | 2852161 3967188 3967190 | ||

| Belt Tensioner | 20491753 21145261 21155561 | ||

| Belt Tensioner | 3974102 4936440 4994573 | ||

| Belt Tensioner | 3973820 3287277 3976834 3957434 4891116 4987964 | ||

| Belt Tensioner | 4980639 5287571 5287571 5267127 | ||

| Belt Tensioner | 55711571 21631484 | ||

| Belt Tensioner | 3937555 3917440 3934819 3936205 5333481 | ||

| Belt Tensioner | 3936210 3914854 3973827 5333480 3934822 | ||

| Belt Tensioner | 3936213 3281583 3934821 3945527 3976831 5259571 | ||

| Belt Tensioner | 3973824 3922549 3925625 3934820 3936206 5333486 | ||

| Belt Tensioner | 3922901 3911621 3934823 3936207 3937556 3976832 5333478 | ||

| Belt Tensioner | 3924026 3921524 3934814 3934816 3936197 3978571 3976833 | ||

| Belt Tensioner | 3914086 3917485 39229 3936201 3937553 5333477 | ||

| 5263262PX | 526326200PX | INJECTOR |

| 4955484NX | 495548400NX | KIT,EXH RCN VALVE |

| 4089981RX | 408998100RX | ACTUATOR, ISX TIMING KIT |

| 5413782RX | 541378200RX | HEAD,CYLINDER |

| 3688268NX | 368826800NX | ALTERNATOR |

| 4089980RX | 408998000RX | ACTUATOR, METERING ISX ENGINE |

| 4955525PX | 495552500PX | KIT,INJ REPAIR |

| 4 0571 62NX | 4 0571 6200NX | KIT,DISTRIBUTOR |

| 5348546RX | 534854600RX | HEAD,CYLINDER |

| 4928260PX | 492826000PX | INJECTOR,HD/HPI |

| 5263308PX | 526330800PX | INJECTOR |

| 34 0571 3RX | RX | MODULE,ELECTRONIC CONTROL |

| 4062569PX | 406256900PX | INJECTOR,HD/HPI |

| 4 0571 62RX | 4 0571 6200RX | FP, CAPS ISC EQUALIZER/ ISL ICV |

| 2882077NX | 2882 0571 0NX | KIT,INJECTOR |

| 4921433NX | 492143300NX | ADAPTER, FUEL PUMP CCR |

| 3687356NX | 368735600NX | COMPRESSOR,2 CYL AIR |

| 435715RX | 43571500RX | KIT,ELEC CONTROL MODULE |

| 5413784RX | 541378400RX | HEAD,CYLINDER |

| 2872405PX | 287240500PX | INJECTOR, XPI |

| 4352232NX | 435223200NX | KIT,TURBOCHARGER |

| 4956078RX | 495607800RX | TURBOCHARGER,HE351W |

| 4956081RX | 49565710RX | KIT,TURBOCHARGER |

| 4955438RX | 495543800RX | KIT, EGR VALVE ISB02 |

| 3684009RX | 368400900RX | MODULE,ELECTRONIC CONTROL |

| 4954907NX | 495490700NX | PUMP,FUEL |

| 5264248NX | 526424800NX | PUMP,FUEL |

| 2894939RX | 289493900RX | SENSOR,NITROGEN OXIHU (WEST LAKE) DIS. |

| 435715NX | 43571500NX | KIT,TURBOCHARGER |

| 2882128NX | 288212800NX | KIT,TURBOCHARGER |

| 4956072NX | 495607200NX | TURBOCHARGER,HE221W |

| 457129RX | 45712900RX | ROD,ENGINE CONNECTING |

| 43 0571 6NX | NX | KIT,EGR VALVE |

| 4089909RX | 408990900RX | PUMP,WATER |

| 3942581RX | 394258100RX | ROD,CONN ISB |

| 5321615RX | 532161500RX | TURBOCHARGER,HE851 |

| 457109RX | 45710900RX | KIT,TURBOCHARGER |

| 405715RX | 40571500RX | PUMP, FUEL HPI COMPACT |

| 457128RX | 45712800RX | ACTUATOR, METERING KIT ISX |

| 3634643RX | 363464300RX | PUMP, LUBE KTA50 |

| 45711NX | 40905710NX | PUMP,WATER |

| 2882091RX | 28825710RX | KIT,TURBOCHARGER |

| 457140RX | 45714000RX | ACTUATOR, TIMING KIT |

| 3964556RX | 396455600RX | PUMP, INJECTION VP44 |

| 4012293NX | 401229300NX | ROD,ENGINE CONNECTING |

| 435713NX | 43571300NX | KIT,TURBOCHARGER |

| 4571870NX | 457187000NX | PUMP, LUBE KIT QST30 |

| 3800499RX | 380049900RX | TURBO, HX82 |

| 4571286RX | 457128600RX | INJECTOR BOSCH QST 30 |

| 4955358RX | 495535800RX | INJECTOR BOSCH QST 30 |

| 4571975NX | 457197500NX | TURBOCHARGER,HX83 WTRCOOL |

| 4955450RX | 495545000RX | TURBO, HX82 |

| 4955640RX | 495564000RX | INJECTOR BOSCH QST 30 |

| 4957127PX | 495712700PX | INJECTOR |

| 4955330NX | 495533000NX | TURBOCHARGER,HE851 |

| 4955331NX | 495533100NX | TURBO, HE851 |

| 4955877RX | 495587700RX | TURBOCHARGER,HE851 |

| 4571571RX | 457157100RX | TURBO, HX82 |

| 4098940NX | 409894000NX | FOLL, CAM K19 |

| 385716RX | 38571600RX | KIT,TURBOCHARGER |

| 4096475NX | 409647500NX | ROD,ENGINE CONNECTING |

| 4 0571 62NX | 4 0571 6200NX | KIT,TURBOCHARGER |

| 3804939RX | 380493900RX | KIT,TURBOCHARGER |

| 2881835NX | 288183500NX | PUMP,INJECTION BOSCH |

| 2881986NX | 288198600NX | KIT,TURBOCHARGER |

| 3 0571 34NX | 3 0571 3400NX | PUMP,INJECTION BOSCH |

| 2881922NX | 288192200NX | KIT,TURBOCHARGER |

| 2881834NX | 288183400NX | PUMP,INJECTION BOSCH |

| 3 0571 33NX | 3 0571 3300NX | PUMP,INJECTION BOSCH |

| 2882130NX | 288213000NX | INJECTOR |

| 2882117NX | 288211700NX | KIT,COMPRESSOR REPAIR |

| 2888810NX | 288881000NX | PUMP,FUEL |

| 2882126NX | 288212600NX | KIT,TURBOCHARGER |

| 2882103NX | 288210300NX | KIT,TURBOCHARGER |

| 3571891NX | 357189100NX | ROD,ENGINE CONNECTING |

| 2882149NX | 288214900NX | KIT,TURBOCHARGER |

| 2882106NX | 288210600NX | KIT,TURBOCHARGER |

| 3634640RX | 363464000RX | PUMP,LUBRICATING OIL |

| 3646326NX | 364632600NX | HEAD,CYLINDER |

| 3646323RX | 364632300RX | HEAD,CYLINDER |

| 4090019RX | 409001900RX | KIT,TURBOCHARGER |

| 5321612RX | 532161200RX | KIT,TURBOCHARGER |

| 4088431PX | 408843100PX | INJECTOR |

| 3092932RX | 309293200RX | ROD,ENGINE CONNECTING |

| 3092935RX | 309293500RX | ROD,ENGINE CONNECTING |

| 4323150RX | 432315000RX | HEAD,CYLINDER |

| 5305268NX | 530526800NX | MODULE,INLET CATALYST |

| 3901383RX | 390138300RX | ROD,CONN 6C |

| 4009877NX | 400987700NX | BODY,FUEL PUMP |

| 3857170RX | 385717000RX | TURBO, KIT HX35 |

| 457174RX | 45717400RX | PUMP,GEAR FUEL |

| 3979571NX | 397957100NX | FUEL PUMP BOSCH VE LFB |

| 3967448NX | 396744800NX | HEAD, CYLINDER 6B |

| 4981626NX | 498162600NX | HEAD,CYLINDER |

| 3967433NX | 396743300NX | HEAD,CYLINDER |

| 457137NX | 45713700NX | KIT,TURBOCHARGER ACTUATOR |

| 4956076NX | 49565710NX | KIT,TURBOCHARGER |

| 4956079NX | 49565710NX | TURBOCHARGER,HE351W |

| 4956070NX | 495607000NX | KIT,TURBOCHARGER |

| 2882016NX | 288201600NX | KIT,TURBOCHARGER |

| 2882017NX | 288201700NX | KIT,TURBOCHARGER |

| 5263307RX | 526330700RX | INJECTOR |

| 2882035NX | 2882 0571 0NX | KIT,TURBOCHARGER |

| 2882052NX | 288205200NX | KIT,TURBOCHARGER |

| 2882055NX | 2882 0571 0NX | KIT,TURBOCHARGER |

| 2882058NX | 2882 0571 0NX | KIT,TURBOCHARGER |

| 2882059NX | 288205900NX | KIT,TURBOCHARGER |

| 2882034NX | 288203400NX | KIT,TURBOCHARGER |

| 2882067NX | 288206700NX | KIT,TURBOCHARGER |

| 2882036NX | 288203600NX | KIT,TURBOCHARGER |

| 2882054NX | 288205400NX | KIT,TURBOCHARGER |

| 2882065NX | 288206500NX | KIT,TURBOCHARGER |

| 2882061NX | 288206100NX | KIT,TURBOCHARGER |

| 2882066NX | 2882 0571 0NX | KIT,TURBOCHARGER |

| 5263312NX | 526331200NX | INJECTOR |

| 2882141NX | 288214100NX | KIT,TURBOCHARGER |

| 2882127NX | 288212700NX | KIT,TURBOCHARGER |

| 43 0571 0NX | NX | KIT,TURBOCHARGER |

| 2882133NX | 288213300NX | KIT,TURBOCHARGER |

| 2882131NX | 288213100NX | KIT,TURBOCHARGER |

| 2882134NX | 288213400NX | KIT,TURBOCHARGER |

| 2882132NX | 288213200NX | KIT,TURBOCHARGER |

| 5273750NX | 527375000NX | INJECTOR |

| 4956016NX | 495601600NX | KIT,TURBOCHARGER |

| 2882140NX | 288214000NX | KIT,TURBOCHARGER |

| 4 0571 82NX | 4 0571 8200NX | KIT,TURBOCHARGER |

| 4309221NX | 430922100NX | KIT,TURBOCHARGER |

| 4 0571 43RX | 4 0571 4300RX | KIT,TURBOCHARGER |

| 4309226NX | 430922600NX | KIT,TURBOCHARGER |

| 4309241NX | 430924100NX | KIT,TURBOCHARGER |

| 5291859NX | 529185900NX | VALVE,EXHAUST GAS RCN |

| 435716NX | 43571600NX | KIT,TURBOCHARGER |

| 4955231NX | 495523100NX | KIT,TURBOCHARGER |

| 5292034NX | 529203400NX | VALVE,EXHAUST GAS RCN |

| 43571NX | 4357100NX | KIT,TURBOCHARGER |

| 4309230NX | 430923000NX | KIT,TURBOCHARGER |

| 4309251NX | 430925100NX | KIT,TURBOCHARGER |

| 4309422NX | 430942200NX | KIT,TURBOCHARGER |

| 4352158NX | 435215800NX | KIT,TURBOCHARGER |

| 4352147NX | 435214700NX | KIT,TURBOCHARGER |

| 4352148NX | 435214800NX | KIT,TURBOCHARGER |

| 4352150NX | 435215000NX | KIT,TURBOCHARGER |

| 4352167NX | 435216700NX | KIT,TURBOCHARGER |

| 4 0571 82RX | 4 0571 8200RX | KIT,TURBOCHARGER |

| 5302660NX | 530266000NX | MODULE,INLET CATALYST |

| 535711PX | 53571710PX | INJECTOR |

| 3603868PL | 360386800PL | PRELUB STR, 50MT 24V 11T |

| 365717RX | 36571700RX | STR,D/R 28MT 24V CW 10T WET |

| 3675270NW | 367527000NW | ALT, BOSCH K-1 12V N 65A 2″ MTG |

| 3675267NW | 367526700NW | STR, 12V 13T 3.0KW B PLUS SPECIAL |

| 3675275NW | 367527500NW | ALT, BOSCH K-1 24V N 45A 2″ MTG |

| 36 0571 4NW | NW | STR, ND 2.7KW 12V 13T DRY W/B TERM |

| 3675291NW | 367529100NW | STARTER, CZPT 24V 10T 5.5KW |

| 3675288NW | 367528800NW | STR, CZPT 12V, 10T, 4.0KW |

| 3675285NW | 367528500NW | STR, CZPT 12V, 13T, 2.7 KW |

| 3675287NW | 367528700NW | STARTER, CZPT 12V, 13T, 2.5KW |

| 3675290NW | 367529000NW | STR, CZPT 24V, 10T, 7.5KW |

| 3964432NW | 396443200NW | STR, CZPT 12V, 13T,2.5KW |

| 3964428NW | 396442800NW | STR, CZPT 12V, 13T, 2.7KW |

| 4951302NW | 495135710NW | ALT, BOSCH 12V 95A |

| 4951315NW | 495131500NW | SWITCH, IMS 39MT 24V |

| 4951316NW | 495131600NW | SWITCH, IMS 39MT 12V |

| 4951317NW | 495131700NW | SWITCH, IMS 38MT 24V |

| 4951318NW | 495131800NW | SWITCH, IMS 38MT 12V |

| 4951303NW | 495130300NW | ALT, BOSCH 12V 160A |

| 4096532NX | 409653200NX | ALTERNATOR |

| 2892050NW | 289205000NW | STARTER, 39 MT, 12V, 11T, OCP/IM |

| 4086503NX | 408650300NX | ALTERNATOR |

| 3686068NX | 368606800NX | ALTERNATOR |

| 5282463NX | 528246300NX | ALTERNATOR |

| 5367755RX | 536775500RX | MOTOR,STARTING |

| 2888247NX | 288824700NX | MODULE,CATALYST |

| 2888261NX | 288826100NX | MODULE,INLET CATALYST |

| 2888262NX | 288826200NX | MODULE,INLET CATALYST |

| 2888246NX | 288824600NX | MODULE,CATALYST |

| 2888248NX | 288824800NX | MODULE,CATALYST |

| 2888249NX | 288824900NX | MODULE,CATALYST |

| 2872281NX | 287228100NX | HEAD,FUEL PUMP |

| 2893586NX | 289358600NX | HEAD,CYLINDER |

| 2880502NX | NX | MODULE,INLET CATALYST |

| 2880506NX | 288050600NX | MODULE,INLET CATALYST |

| 2880507NX | 288050700NX | MODULE,INLET CATALYST |

| 288571NX | 28857100NX | MODULE,INLET CATALYST |

| 2880582NX | 288058200NX | MODULE,INLET CATALYST |

| 2875719NX | 287571900NX | PUMP,WATER |

| 2880501NX | NX | MODULE,INLET CATALYST |

| 2880165NX | 288016500NX | MODULE,CATALYST |

| 2888250NX | 288825000NX | MODULE,INLET CATALYST |

| 2888252NX | 288825200NX | MODULE,INLET CATALYST |

| 2888253NX | 288825300NX | MODULE,INLET CATALYST |

| 2888251NX | 288825100NX | MODULE,INLET CATALYST |

| 2888263NX | 288826300NX | MODULE,INLET CATALYST |

| 2888257NX | 288825700NX | MODULE,INLET CATALYST |

| 2872518NX | 287251800NX | ADAPTER,FUEL PUMP |

| 5287396NX | 528739600NX | MODULE,CATALYST |

| 2894920NX | 289492000NX | INJECTOR |

| 2882082NX | 288208200NX | KIT,TURBOCHARGER |

| 2882138NX | 288213800NX | KIT,TURBOCHARGER |

| 2882137NX | 288213700NX | KIT,TURBOCHARGER |

| 435715NX | 43571500NX | KIT,TURBOCHARGER |

| 5289643NX | 528964300NX | MODULE,INLET CATALYST |

| 5289745NX | 528974500NX | MODULE,INLET CATALYST |

| 5288789NX | 528878900NX | MODULE,INLET CATALYST |

| 5289645NX | 528964500NX | MODULE,INLET CATALYST |

| 2899644NX | 289964400NX | HEAD,CYLINDER |

| 2885719NX | 288571900NX | MODULE,INLET CATALYST |

| 5315264NX | 531526400NX | MODULE,INLET CATALYST |

| 4972994RX | 497299400RX | CPR, AIR 2 CYL N14/ISM 37.4 CFM |

| 2881725NX | 288172500NX | KIT,EGR COOLER |

| 5287520NX | 528752000NX | MODULE,INLET CATALYST |

| 5287191NX | 528719100NX | MODULE,INLET CATALYST |

| 5287518NX | 528751800NX | MODULE,CATALYST |

| 3811995RX | 381199500RX | ROD,CONN QSK19 |

| 4928349RX | 492834900RX | INJECTOR |

| 3641566NX | 364156600NX | HEAD,CYLINDER |

| 3096326NX | 309632600NX | PUMP,LUBRICATING OIL |

| 2882079NX | 28825710NX | KIT,INJ REPAIR |

| 2882096NX | 288209600NX | KIT,TURBOCHARGER |

| 2882092NX | 288209200NX | KIT,TURBOCHARGER |

| 3646783NX | 364678300NX | HEAD,CYLINDER |

| 3647147NX | 364714700NX | HEAD,CYLINDER |

| 457165RX | 45716500RX | TURBO, HX83 QSK19-C |

| 4956137RX | 495613700RX | TURBOCHARGER,HX83 WTRCOOL |

| 4306516NX | 430651600NX | PUMP,INJECTION BOSCH |

| 4306517NX | 430651700NX | PUMP,FUEL |

| 5328119RX | 532811900RX | KIT,TURBOCHARGER |

| 2872621NX | 287262100NX | INJECTOR |

| 4307026NX | 430702600NX | ADAPTER,FUEL PUMP |

| 4955542NX | 495554200NX | KIT,TURBOCHARGER |

| 3677046NX | 367704600NX | COS FUEL PUMP ISL |

| 3677041NX | 36775710NX | COS GEAR PUMP KIT ISL |

| 3677045NX | 367704500NX | COS FUEL PUMP EQUALIZER |

| 3677044NX | 367704400NX | COS FUEL PUMP STHangZhouRD |

| 4956092NX | 495609200NX | KIT,EGR VALVE |

| 2881975NX | 288197500NX | KIT,TURBOCHARGER |

| 2871469NX | 287146900NX | MODULE,CATALYST |

| 2880153NX | 288015300NX | MODULE,CATALYST |

| 2871929NX | 287192900NX | MODULE,INLET CATALYST |

| 288 0571 NX | NX | MODULE,INLET CATALYST |

| 2885880NX | 288588000NX | MODULE,INLET CATALYST |

| 288571NX | 28857100NX | MODULE,CATALYST |

| 288571NX | 28857100NX | MODULE,CATALYST |

| 4956100NX | 495610000NX | KIT,TURBOCHARGER |

| 4956099NX | 49565710NX | TURBOCHARGER,HX40W |

| 4956095NX | 495609500NX | TURBOCHARGER,HX40W |

| 2881809NX | 288180900NX | KIT,TURBOCHARGER |

| 4956096NX | 495609600NX | TURBOCHARGER,HX40W |

| 4956098NX | 495609800NX | TURBOCHARGER,HX40W |

| 2881976NX | 288197600NX | KIT,TURBOCHARGER |

| 2881949NX | 288194900NX | KIT,TURBOCHARGER |

| 4989266NX | 498926600NX | PUMP,FUEL |

| 2881950NX | 288195000NX | KIT,TURBOCHARGER |

| 2881939NX | 288193900NX | KIT,TURBOCHARGER |

| 2881983NX | 288198300NX | KIT,TURBOCHARGER |

| 2880589NX | 288058900NX | MODULE,CATALYST |

| 2880497NX | 288049700NX | MODULE,CATALYST |

| 2871569NX | 287156900NX | MODULE,CATALYST |

| 288571NX | 28857100NX | MODULE,CATALYST |

| 2871753NX | 287175300NX | MODULE,INLET CATALYST |

| 288571NX | 28857100NX | MODULE,CATALYST |

| 5268436NX | 526843600NX | INJECTOR |

| 2882040NX | 288204000NX | KIT,TURBOCHARGER |

| 2880154NX | 288015400NX | MODULE,INLET CATALYST |

| 2880588NX | 288058800NX | MODULE,INLET CATALYST |

| 2880491NX | 288049100NX | MODULE,INLET CATALYST |

| 5287472NX | 528747200NX | MODULE,INLET CATALYST |

| 5287488NX | 528748800NX | MODULE,INLET CATALYST |

| 5287490NX | 528749000NX | MODULE,CATALYST |

| 5287487NX | 528748700NX | MODULE,INLET CATALYST |

| 5287474NX | 528747400NX | MODULE,INLET CATALYST |

| 5287478NX | 528747800NX | MODULE,INLET CATALYST |

| 5287489NX | 528748900NX | MODULE,INLET CATALYST |

| 5287475NX | 528747500NX | MODULE,INLET CATALYST |

| 5287491NX | 528749100NX | MODULE,INLET CATALYST |

| 5273898NX | 527389800NX | COMPRESSOR,1 CYL AIR |

| 5273897NX | 527389700NX | COMPRESSOR,1 CYL AIR |

| 435712NX | 43571200NX | KIT,TURBOCHARGER |

| 4309223NX | 430922300NX | KIT,TURBOCHARGER |

| 5272937NX | 527293700NX | INJECTOR |

| 4309228NX | 430922800NX | KIT,TURBOCHARGER |

| 435711NX | 43571100NX | HEAD,FUEL PUMP |

| 4352214NX | 435221400NX | KIT,TURBOCHARGER |

| 5292257NX | 529225700NX | MODULE,INLET CATALYST |

| 4376312RX | 437631200RX | KIT,EXH RCN COOLER |

| 288571RX | 28857100RX | MODULE,INLET CATALYST |

| 4384224RX | 438422400RX | PUMP,FUEL |

| 4932265NX | 493226500NX | COMPRESSOR,1 CYL AIR |

| 4947582NX | 494758200NX | INJ, ISF3.8 |

| 5264272NX | 526427200NX | INJECTOR |

| 5283275NX | 528327500NX | INJECTOR |

| 435713NX | 43571300NX | KIT,TURBOCHARGER |

| 43 0571 9NX | 43095710NX | KIT,TURBOCHARGER |

| 435714NX | 43571400NX | KIT,TURBOCHARGER |

| 4309205NX | 430920500NX | KIT,TURBOCHARGER |

| 4026886NX | 402688600NX | IDLER PULLEY SIGNATURE 600 |

| 4307411NX | 430741100NX | ACTUATOR,ETR FUEL CONTROL |

| 2881718NX | 288171800NX | KIT,TURBOCHARGER |

| 2897518NX | 289751800NX | INJECTOR |

| 2899630NX | 289963000NX | PUMP,WATER |

| 4032855NX | 403285500NX | KIT,TUR HOUSING REPAIR |

| 4032856NX | 403285600NX | KIT,TURBOCHARGER HOUSING |

| 4032857NX | 403285700NX | KIT,TUR HOUSING REPAIR |

| 4032866NX | 403286600NX | KIT,TURBOCHARGER HOUSING |

| 4032867NX | 403286700NX | KIT,TURBOCHARGER HOUSING |

| 4032868NX | 403286800NX | KIT,TURBOCHARGER HOUSING |

| 4032874NX | 403287400NX | KIT,TURBOCHARGER HOUSING |

| 43 0571 1NX | NX | PUMP,FUEL |

| 4307050NX | 430705000NX | HEAD,FUEL PUMP |

| 4307217NX | 430721700NX | INJECTOR |

| 435711NX | 43571100NX | KIT,TURBOCHARGER |

| 4309288NX | 430928800NX | KIT,TURBOCHARGER |

| 4309294NX | 430929400NX | KIT,TURBOCHARGER |

| 4309295NX | 430929500NX | KIT,TURBOCHARGER |

| 4309296NX | 430929600NX | KIT,TURBOCHARGER |

| 4309297NX | 430929700NX | TURBOCHARGER |

| 4309298NX | 430929800NX | KIT,TURBOCHARGER |

| 43 0571 0NX | NX | KIT,TURBOCHARGER |

| 43 0571 1NX | 43571710NX | KIT,TURBOCHARGER |

| 43 0571 4NX | NX | KIT,TURBOCHARGER |

| 435710NX | 43571000NX | KIT,TURBOCHARGER |

| 435712NX | 43571200NX | KIT,TURBOCHARGER |

| 435714NX | 43571400NX | KIT,TURBOCHARGER |

| 435715NX | 43571500NX | KIT,TURBOCHARGER |

| 435719NX | 43571900NX | KIT,TURBOCHARGER |

| 435710NX | 43571000NX | KIT,TURBOCHARGER |

| 435711NX | 43571100NX | KIT,TURBOCHARGER |

| 435712NX | 43571200NX | KIT,TURBOCHARGER |

| 435713NX | 43571300NX | KIT,TURBOCHARGER |

| 435714NX | 43571400NX | KIT,TURBOCHARGER |

| 435715NX | 43571500NX | KIT,TURBOCHARGER |

| 435716NX | 43571600NX | KIT,TURBOCHARGER |

| 435717NX | 43571700NX | KIT,TURBOCHARGER |

| 435718NX | 43571800NX | KIT,TURBOCHARGER |

| 435718NX | 43571800NX | KIT,TURBOCHARGER |

| 435715NX | 43571500NX | TURBOCHARGER,HE 07 VG MR |

| 435718NX | 43571800NX | KIT,TURBOCHARGER |

| 4309404NX | 430940400NX | KIT,TURBOCHARGER |

| 4309407NX | 430940700NX | KIT,TURBOCHARGER |

| 4309408NX | 430940800NX | KIT,TURBOCHARGER |

| 43 0571 4NX | NX | KIT,EGR VALVE |

| 43571NX | 4357100NX | KIT,TURBOCHARGER |

| 4328760NX | 432876000NX | MODULE,INLET CATALYST |

| 4328822NX | 432882200NX | MODULE,INLET CATALYST |

| 4329943NX | 432994300NX | MODULE,INLET CATALYST |

| 4352159NX | 435215900NX | KIT,TURBOCHARGER |

| 4352172NX | 435217200NX | KIT,TURBOCHARGER |

| 4352175NX | 435217500NX | KIT,TURBOCHARGER |

| 4352177NX | 435217700NX | KIT,TURBOCHARGER |

| 4352180NX | 435218000NX | KIT,TURBOCHARGER |

| 4352182NX | 435218200NX | KIT,TURBOCHARGER |

| 4352189NX | 435218900NX | KIT,TURBOCHARGER |

| 4352196NX | 435219600NX | KIT,TURBOCHARGER |

| 4352200NX | 435220000NX | KIT,TURBOCHARGER |

| 4352202NX | 435225710NX | KIT,TURBOCHARGER |

| 4352205NX | 435220500NX | KIT,TURBOCHARGER |

| 4352206NX | 435220600NX | KIT,TURBOCHARGER |

| 4352207NX | 435220700NX | KIT,TURBOCHARGER |

| 4352208NX | 435220800NX | KIT,TURBOCHARGER |

| 4352209NX | 435220900NX | KIT,TURBOCHARGER |

| 4352213NX | 435221300NX | KIT,TURBOCHARGER |

| 4352215NX | 435221500NX | KIT,TURBOCHARGER |

| 4352224NX | 435222400NX | KIT,TURBOCHARGER |

| 4352225NX | 435222500NX | KIT,TURBOCHARGER |

| 4352226NX | 435222600NX | KIT,TURBOCHARGER |

| 4352229NX | 435222900NX | KIT,TURBOCHARGER |

| 4352231NX | 435223100NX | KIT,TURBOCHARGER |

| 4352233NX | 435223300NX | KIT,TURBOCHARGER |

| 4352234NX | 435223400NX | KIT,TURBOCHARGER |

| 4352235NX | 435223500NX | KIT,TURBOCHARGER |

| 4352236NX | 435223600NX | KIT,TURBOCHARGER |

| 4352317NX | 435231700NX | KIT,TURBOCHARGER |

| 4352318NX | 435231800NX | KIT,TURBOCHARGER |

| 4352319NX | 435231900NX | KIT,TURBOCHARGER |

| 4352320NX | 435232000NX | KIT,TURBOCHARGER |

| 5284269NX | 528426900NX | MODULE,INLET CATALYST |

| 5289951NX | 528995100NX | MODULE,INLET CATALYST |

| 5289955NX | 528995500NX | MODULE,INLET CATALYST |

| 5357158NX | 535715800NX | MODULE,INLET CATALYST |

| 5301988NX | 530198800NX | MODULE,INLET CATALYST |

| 5302661NX | 530266100NX | MODULE,INLET CATALYST |

| 5302662NX | 530266200NX | MODULE,INLET CATALYST |

| 5357115NX | 535711500NX | MODULE,INLET CATALYST |

| 5357116NX | 535711600NX | MODULE,INLET CATALYST |

| 5357118NX | 535711800NX | MODULE,INLET CATALYST |

| 5357124NX | 535712400NX | MODULE,INLET CATALYST |

| 5357126NX | 535712600NX | MODULE,INLET CATALYST |

| 5357127NX | 535712700NX | MODULE,INLET CATALYST |

| 5357128NX | 535712800NX | MODULE,INLET CATALYST |

| 5357129NX | 535712900NX | MODULE,INLET CATALYST |

| 5357132NX | 535713200NX | MODULE,INLET CATALYST |

| 5304054NX | 530405400NX | MODULE,CATALYST |

| 5304892NX | 530489200NX | VALVE,BYPASS |

| 5307004NX | 530700400NX | MODULE,INLET CATALYST |

| 53 0571 2NX | NX | MODULE,INLET CATALYST |

| 5310175NX | 531017500NX | MODULE,INLET CATALYST |

| 5312368NX | 531236800NX | MODULE,CATALYST |

| DR7042NX | DR0704200NX | ENG ISX 15 13 B 500@1800 XPI |

| DR7046NX | DR0704600NX | ENG ISX 15 13 B 450@1650 XPI |

| DR7048NX | DR57100NX | ENG ISX 15 13 B 600@1900 XPI |

| DR7690NX | DR 0571 000NX | ENG X15 16 B 605@1950 XPI |

| DR7691NX | DR 0571 100NX | ENG X15 16 B 450@1800 XPI |

| 3078195PX | 307819500PX | INJECTOR |

| 357116PX | 35711600PX | INJ,CELECT N14 NTS PHASE II |

| 3095055PX | 3095 0571 0PX | INJECTOR |

| 3349821PX | 334982100PX | INJECTOR |

| 3411753RX | 341175300RX | INJ, CELECT 96M11 PLUS |

| 3411756PX | 341175600PX | INJ,CELECT 98M11 ISM |

| 3411760PX | 341176000PX | INJ,CELECT 95NE2-94NE3 |

| 3411760RX | 341176000RX | INJ, CELECT 95NE2-94NE3 |

| 3411763RX | 341176300RX | INJ, CELECT 94 NE3 |

| 3411764PX | 341176400PX | INJ, CELECT 95 N14 EURO 2 |

| 3411766RX | 341176600RX | INJ, CELECT 99 NE2 |

| 3411767PX | 341176700PX | INJ,CELECT 98N14 |

| 3411821PX | 341182100PX | INJECTOR |

| 3652541RX | 365254100RX | INJ, CELECT N14 PHASE 1 |

| 3652542PX | 365254200PX | INJ,CELECT 91N14 PHASE II |

| 3652542RX | 365254200RX | INJ,CELECT 91N14 PHASE II |

| 4026222PX | 402622200PX | INJ, CELECT 99M11 DEFENDER |

| 4061851RX | 406185100RX | INJ, CELECT EURO III M11 |

| 4957121PX | 495712100PX | INJ, CELECT ISM02 |

| 4903319PX | 490331900PX | INJ, CELECT |

| 4903472PX | 490347200PX | INJ, M11 QSM3 TIER III |

| 4928171PX | 492817100PX | INJ, CELECT 98M |

| 4955524PX | 495552400PX | KIT,INJ REPAIR |

HangZhou CZPT Industry & Trade Co., Ltd.

Add:Haili Industry Park ,HangZhou City ,ZheJiang Province,China

Post Code:442013

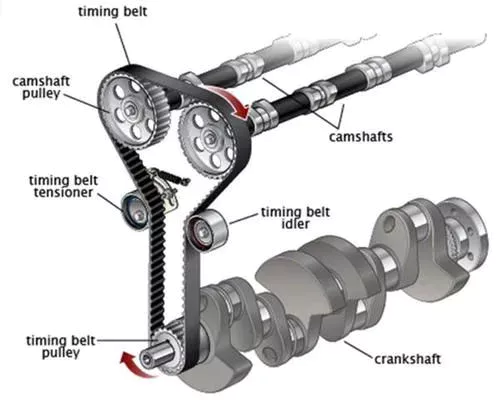

engine

How to Repair a Timing Belt Tensioner

Your timing belt tensioner is a critical component of your vehicle’s drivetrain. Too little tension, for example, will cause the belt to slip, and too much tension can overload shaft bearings, leading to premature failure. If you notice that your belt tensioner is not working properly, you should immediately visit a mechanic. Corrosion from road splash, dirt, mud, or other debris can jam the tensioner housing. To avoid this, make sure that you replace your timing belt tensioner as soon as possible.

Symptoms of a bad belt tensioner

If you’ve ever wondered what signs indicate a bad belt tensioner, look no further than your vehicle’s engine. Worn belts or a broken tensioner can cause an irritating squealing noise, as well as the belt to slip. Even worse, a bad tensioner can cause water to enter the belt and pulley, resulting in water damage. A worn tensioner is usually the culprit of the noise, but there are also other warning signs that a belt is in trouble.

Your vehicle’s engine may start to run poorly or even squeal when you turn the key. Similarly, your engine may fail to start at all, or the check engine light may illuminate. The belt may also start to wear out in an unusual pattern. These signs indicate that the tensioner is in need of replacement. If you notice 1 or more of these signs, get your car checked right away.

To check the condition of the tensioner, remove the drive belt and observe the pulley. You may notice rust dripping or bleeding at the mounting bolts, which are the most common signs of a bad tensioner. If you can’t remove the drive belt, check the pulley by rotating it. If you feel resistance, the pulley is likely worn or slack.

Failure of the belt tensioner will also cause other parts of the car to fail. If a bad belt tensioner isn’t fixed quickly, you might not be able to use the vehicle properly. You could end up breaking your car’s engine, losing power steering, and possibly even the water pump. If your car is not running right, you could be stuck in the middle of nowhere. Even if the alternator doesn’t work, you’ll still have a malfunctioning power steering system and a dead AC system.

A broken timing belt tensioner can cause strange noises or a no-start condition. These noises and symptoms are signs of a bad belt tensioner, and you’ll have to replace it ASAP. If you don’t know what symptoms mean, don’t hesitate to take your car to a mechanic. You’ll be surprised how easy it is to check this vital component and save yourself a bunch of money.

Components of a belt tensioner

The components of a belt tensioner assembly consist of 4 key components. The clearance between the pulley and the base is critical to the tensioner’s operation. If the tensioner is installed incorrectly, the spring can break and cause severe injury. The spring’s preload and powerful force make it difficult to service the unit safely. These parts are non-serviceable. If you are unsure of how to repair your tensioner, contact an authorized mechanic.

The components of a belt tensioner drive are shown in FIG. 2. The rotor shaft is connected to the drive screw, while the second transmission is connected to the gear shaft. The rotor and gear shaft are in parallel with each other. The gear shaft and worm wheel are connected to the belt tensioner drive. In other words, the belt tensioner drive is located in the B-pillar of the motor vehicle.

A belt tensioner may be equipped with a drive shaft and electric motor. The drive shaft may also contain a worm gear or worm wheel. The drive shaft also has an intermediate gearbox. Once the tensioner is set, it is ready to move to its safe-position position. It is a relatively simple and inexpensive replacement for your belt. When replacing a multi-ribbed belt, be sure to replace the tensioner along with the belt. Gates recommends replacing all wear parts at once.

In the event of a faulty drive belt tensioner, the belt will not stay taut. The pulley can wobble and cause the belt to fray. In addition to this, the bearings can cause a loud squealing noise. In this case, the accessory motors will continue to run, while the belt itself will not. Therefore, replacing the timing belt tensioner is an important part of maintaining the car.

In some systems, the belt tensioner uses a worm gear as the first gear. This results in rolling engagement of the screw’s teeth. This reduces noise and vibrations, while maximizing the efficiency of the belt tensioner drive. Additionally, a worm gear can eliminate the need for additional parts in belt tensioners. While this may not be practical in all instances, it is a good choice for space-constrained environments.

Repair options for a timing belt tensioner

A timing belt tensioner is an essential part of an automobile’s timing chain and is responsible for ensuring proper timing. Proper alignment of timing marks is essential to the proper operation of the engine, and improper alignment may lead to damage to the engine. To repair a timing belt tensioner, there are several repair options available. First, you need to remove the engine cover. You can then remove the timing belt tensioner by loosening the pulley using a ratchet or breaker bar.

When the timing belt isn’t properly tensioned, the engine will misfire. The engine misfires when the valve opens and the pistons rise at the wrong time. When this happens, the timing belt cannot properly grip the gears and the engine will not function. If this part fails, you’ll have to replace the whole timing chain. However, if you are handy with tools, you can easily replace the entire timing belt tensioner yourself.

If your timing belt tensioner is out of alignment, you should replace it. If you’re not sure whether it needs to be replaced, check it with a professional and learn the details of the repair. The timing belt tensioner is the most critical part of the engine, so it’s important to know about it. Otherwise, your car won’t run as well as it could. Repair options for a timing belt tensioner will vary depending on the severity of the problem and how much damage it has done.

While there are several repair options for a timing belt tensioner, the average cost of replacement is $364 to $457, and this doesn’t take into account any tax or fee you may be charged. DIY repair methods will usually cost you $50 to $150, and you’ll likely save a lot of money in the process. However, you need to remember that you may be unable to do the job yourself because you don’t know how to use the proper tools and equipment.

While it is not difficult to replace a timing belt tensioner on your own, you should know that you’ll need to remove other parts of the engine as well as special tools to make the repair properly. This is an advanced repair job and requires a great deal of skill. If you’re new to home car repair, you may not want to attempt it yourself. There are many other options, such as hiring a mechanic.

Installation instructions

While there are no universal installation instructions for belt tensioners, the manufacturer of your car may provide detailed instructions. Before attempting to replace your tensioner, read the manufacturer’s recommended procedures carefully. To install a new tensioner properly, unload the old 1 and take a picture or sketch of how the belt should be routed. Once the old tensioner is out, follow the manufacturer’s torque specifications. Make sure to unload and remove the belt from the tensioner, and follow the manufacturer’s torque specifications to install the new one.

If your car comes with a manual belt tensioner, you can follow the instructions. The manual will have a corresponding guide for installation. When installing a belt tensioner, make sure the manual clearly states the static tension for your particular model. Check that it is in line with the engine relief to ensure proper belt tension. You can then use a 6mm allen key to turn the tensioner clockwise and counterclockwise. Once it is in position, release the tensioner to operate. The belt tensioner should now apply the proper tension to your belt.

Before installing a new belt tensioner, make sure you read the manual completely. You should follow these steps carefully to avoid any problems with the tensioner. If the tensioner has failed, you must replace it immediately. A new belt tensioner will help you ensure proper performance of your accessory belt drive system. If you are installing a new multi-ribbed belt, you should replace the tensioner as well. However, it is important to note that replacing the belt tensioner is a complicated process and requires a mechanic to be able to safely remove the belt from the engine.

To install a second stage drive belt, walk the belt onto the input drive and generator. Ensure that the belt is seated properly in the grooves of the pulleys. Next, replace the input drive belt and right and left Drive Disk covers. Test the machine to ensure that it is working properly. If it doesn’t, replace the original drive belt. After installing the new belt, you may want to read the manual again to make sure it is in perfect condition.