Product Description

Product Description

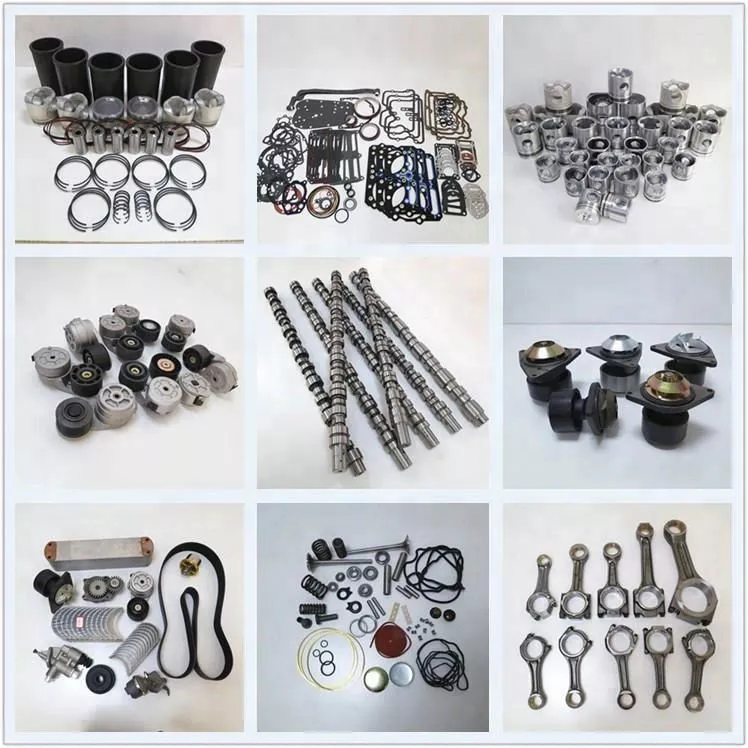

Kutway High Quality Auto parts Car Belt Tensioner

OEM:/ fit for AUDI VW

| Product description: | fit for AUDI VW |

| OEM: | / |

| Brand: | Kutway |

Detailed Photos

Company information

FAQ

Company Profile

With the rapid development of China’s auto parts aftermarket and China’s manufacturing industry. HangZhou CZPT Auto Parts Trading Co., Ltd. and its high-end brands CZPT and BORWATE came into being in 2019! Constantly committed to promoting the healthy development of China’s auto parts industry!

As an innovator and leader in the field of auto parts and an independent brand operating unit, HangZhou Kutewei Auto Parts Trading Co., Ltd. has continuously devoted itself to scientific research, design, development, production and sales. Determined to become a global, comprehensive auto parts trading company with excellent product quality, fair prices and top services. The tenet of our enterprise is: service, quality, innovation, and CZPT situation. Our independent brands CZPT and BORWATE are exported to more than 60 countries in Europe, America, the Middle East, South America, Africa, Southeast Asia, etc. and have won unanimous praise from customers!

At present, KUTWAY’s main products are: suspension system, engine system, cooling system, transmission system, brake system, ignition system, fuel system, appearance parts, 8 categories, and about 20,000 kinds of auto parts. CZPT has a mature German technical product production and supply chain to ensure the stability of product quality, and our products have a two-year or 80,000-kilometer quality guarantee. In addition, we have a professional team to provide customers with 24/7 online after-sales service and online installation guidance to strive for customer satisfaction! One time cooperation, lifelong cooperation! Mutual benefit and win-win!

For a long time, CZPT has a strong technical research and development team, introduced world-class production equipment, and cooperated with domestic well-known universities and scientific research institutions to develop a research and development platform to develop independent technology, shorten the research and development cycle, and pass the ISO9001 quality verification. Many successful applications It has a national patent, and its products are widely used in all kinds of German auto models. It has signed perennial cooperation agreements with dozens of auto manufacturers and maintenance companies at home and abroad, and has not made a positive contribution to building an independent brand of Chinese auto parts.

According to the country’s requirements for energy saving and environmental protection in the production of auto parts, CZPT continues to innovate and develop its development model to make its products and services more perfect. The company actively responds to the scientific development strategy of “people-oriented, CZPT cooperation”, effectively safeguards the interests of customers, pays attention to protecting the rights and interests of employees, and provides inexhaustible impetus for the healthy development and continuous progress of the enterprise.

Business philosophy: reform and innovation, quality is king, to be a first-class brand supplier.

Operating principles: integrity management, inclusive of all rivers.

Business purpose: service, quality, innovation, and CZPT situation.

How do innovations and advancements in V-belt tensioner technology impact their use?

Innovations and advancements in V-belt tensioner technology have a significant impact on their use, bringing about improvements in performance, efficiency, reliability, and ease of installation. These advancements have led to the development of more sophisticated and versatile tensioners that offer enhanced functionality and benefits. Here’s a detailed explanation of how innovations and advancements in V-belt tensioner technology impact their use:

- Improved Tensioning Accuracy:

- Enhanced Belt Lifespan:

- Increased System Efficiency:

- Ease of Installation and Maintenance:

- Compatibility with Diverse Applications:

- Enhanced Safety and Reliability:

Newer tensioner designs incorporate advanced mechanisms that provide improved tensioning accuracy. These technologies enable precise tension control, ensuring optimal belt performance and reducing the risk of belt slippage or excessive wear. The use of innovative tensioning systems, such as automatic tensioners with adaptive tension control, allows for real-time adjustments based on belt condition and operating conditions, further enhancing accuracy and reliability.

Advancements in tensioner technology contribute to the extended lifespan of V-belts. Tensioners with features like self-adjusting mechanisms or constant tension systems help maintain the optimal tension throughout the belt’s life, minimizing wear and fatigue. This results in longer belt life, reduced maintenance requirements, and lower overall operating costs.

Innovative tensioner designs focus on improving system efficiency by reducing energy losses and optimizing power transmission. Tensioners with low-friction components, improved bearing technologies, or dynamic tension control systems help minimize energy consumption and maximize the efficiency of V-belt systems. This is particularly important in applications where energy efficiency is a priority, such as automotive engines or industrial power transmission systems.

Advancements in tensioner technology often result in designs that offer simplified installation procedures and enhanced ease of maintenance. Features like tool-less belt tensioning mechanisms, integrated belt alignment guides, or quick-release systems facilitate faster and more convenient tensioner installation or replacement. Additionally, advancements in materials and coatings used in tensioner construction may provide improved durability, reducing the need for frequent maintenance or replacement.

Innovative tensioner designs aim to provide compatibility with a wide range of applications and systems. Manufacturers develop tensioners in various sizes, configurations, and mounting options to accommodate diverse industrial or automotive needs. This versatility allows for easier integration of tensioners into different systems, expanding their usability and applicability across various industries.

Advancements in tensioner technology contribute to improved safety and reliability of V-belt systems. Features such as built-in protective covers, belt failure detection systems, or advanced tension monitoring capabilities enhance the safety of operators and prevent catastrophic failures. These innovations provide early warnings for potential belt or tensioner issues, allowing for timely maintenance or replacement and reducing the risk of unexpected downtime or accidents.

In summary, innovations and advancements in V-belt tensioner technology have a profound impact on their use. These advancements result in improved tensioning accuracy, enhanced belt lifespan, increased system efficiency, ease of installation and maintenance, compatibility with diverse applications, and enhanced safety and reliability. As tensioner technology continues to evolve, it drives the overall improvement of V-belt systems, offering greater performance, efficiency, and reliability in various industrial and automotive applications.

Can V-belt tensioners be customized or modified to suit specific industrial or automotive needs?

V-belt tensioners can indeed be customized or modified to suit specific industrial or automotive needs. The design and functionality of tensioners can be tailored to meet the requirements of different applications, ensuring optimal performance and compatibility with specific systems. Here’s a detailed explanation of how V-belt tensioners can be customized or modified:

- Tensioner Design:

- Automatic Tensioning Mechanism:

- Tension Adjustment Range:

- Material and Coating Selection:

- Special Features or Accessories:

The design of V-belt tensioners can be customized to accommodate various factors, such as space limitations, mounting configurations, and pulley arrangements. Manufacturers can develop tensioners with different shapes, sizes, and mounting options to ensure proper fitment within specific industrial or automotive applications. This allows for seamless integration of tensioners into existing systems or equipment.

The automatic tensioning mechanism in V-belt tensioners can be customized to suit specific needs. Different types of tensioners, such as spring-loaded tensioners or hydraulic tensioners, can be selected based on the application requirements. The tensioning force or pressure applied by the mechanism can also be adjusted or customized to achieve the desired tension levels for optimal belt performance.

The tension adjustment range of V-belt tensioners can be modified to cater to specific needs. Some applications may require a wider range of tension adjustment to accommodate variations in belt wear or elongation over time. Manufacturers can customize tensioners to provide a broader or narrower range of tension adjustment, allowing for precise tension control based on the specific requirements of the system.

The choice of materials and coatings for V-belt tensioners can be customized to suit specific industrial or automotive needs. Different materials, such as steel, aluminum, or polymers, can be used based on factors such as strength, durability, weight, and corrosion resistance. Similarly, suitable coatings or surface treatments can be applied to enhance the performance and longevity of tensioners in specific operating conditions.

In certain cases, V-belt tensioners may require additional features or accessories to meet specific needs. Manufacturers can incorporate special features or accessories into tensioner designs based on the application requirements. These may include features such as built-in belt alignment guides, idler pulleys, or protective covers to enhance belt stability, alignment, or safety in particular industrial or automotive environments.

In summary, V-belt tensioners can be customized or modified to suit specific industrial or automotive needs. Customization options include the design of tensioners, the selection of automatic tensioning mechanisms, adjustment range modification, material and coating selection, as well as the incorporation of special features or accessories. By customizing or modifying tensioners, manufacturers can ensure optimal performance, compatibility, and longevity in various industrial or automotive applications.

Can you explain the significance of proper tensioning in V-belt-driven machinery and equipment?

Proper tensioning plays a crucial role in V-belt-driven machinery and equipment. It is essential for ensuring optimal performance, efficient power transmission, and extended component life. Here’s a detailed explanation of the significance of proper tensioning in V-belt-driven systems:

- Effective Power Transmission:

- Prevention of Slippage:

- Extended Component Life:

- Reduced Maintenance Requirements:

- Optimized System Performance:

- Enhanced Safety:

Proper tensioning is vital for effective power transmission in V-belt-driven machinery and equipment. The tension applied to the V-belt ensures that it remains tightly engaged with the pulleys, creating frictional forces necessary for transferring power. Insufficient tension can result in slippage between the belt and the pulleys, leading to power loss, reduced efficiency, and compromised performance. By maintaining the correct tension, V-belt-driven systems can achieve efficient power transmission, ensuring that the machinery operates at its intended power output.

One of the primary functions of proper tensioning is to prevent slippage between the V-belt and the pulleys. Slippage occurs when the belt loses traction with the pulleys, leading to inefficient power transmission and reduced performance. Proper tensioning ensures that the V-belt remains securely engaged with the pulleys, minimizing the risk of slippage even under varying loads or during sudden changes in speed or torque. By preventing slippage, proper tensioning helps maintain reliable power delivery, consistent operation, and accurate timing in timing belt applications.

Proper tensioning significantly contributes to the extended life of V-belts and other components in V-belt-driven machinery. When the tension is too loose, the V-belt can experience excessive flexing, leading to premature wear, fatigue, and ultimately, failure. On the other hand, excessive tension can cause increased stress on the V-belt and the pulleys, leading to accelerated wear and potential damage. By maintaining the correct tension, V-belts experience optimal operating conditions, reduced wear, and prolonged lifespan. Proper tensioning also helps minimize stress on other components, such as bearings, shafts, and pulleys, further extending their service life.

Proper tensioning in V-belt-driven machinery can help reduce maintenance requirements. Inadequate tension or slippage can lead to various issues that require frequent maintenance, adjustments, or component replacements. These issues may include belt misalignment, premature wear, increased heat generation, or even system failures. By maintaining the correct tension, V-belt systems operate within their designed parameters, minimizing the occurrence of these problems. Reduced maintenance needs not only save time and effort but also contribute to lower maintenance costs and increased productivity.

Proper tensioning is essential for achieving optimized system performance in V-belt-driven machinery and equipment. When the V-belt is appropriately tensioned, it operates efficiently, minimizing energy losses and maximizing power transmission. This, in turn, leads to improved overall system performance, higher productivity, and reduced operating costs. Proper tensioning ensures that the machinery operates at its intended power levels, maintains accurate timing, and delivers consistent performance, resulting in reliable and efficient operation.

Proper tensioning also contributes to enhanced safety in V-belt-driven machinery and equipment. Slippage or inadequate tension can lead to sudden belt failures, unexpected power losses, or even accidents. By maintaining the correct tension, the risk of such incidents is significantly reduced. Properly tensioned V-belts ensure reliable power transmission, minimizing the potential for unexpected equipment malfunctions or sudden stops. This enhances operator safety and helps prevent damage to the machinery or surrounding equipment.

In summary, proper tensioning is of utmost importance in V-belt-driven machinery and equipment. It ensures effective power transmission, prevents slippage, extends component life, reduces maintenance requirements, optimizes system performance, and enhances safety. By maintaining the correct tension, V-belt-driven systems operate efficiently, reliably, and safely, contributing to increased productivity, reduced downtime, and improved overall operational performance.

editor by CX 2024-01-12

China Standard High Quality Tensioner Bearing Vkm31099 534037410 Tensioner Bearing Assembly near me factory

Product Description

Product Description

|

Item Name |

Belt tensioner bearing |

||||

|

Material |

Steel | ||||

|

Size |

Diameter: 76,3 mm Width: 25,7 mm |

||||

| Inspection | 1 2-44-014 53457110 8641 293036 VKM31099 V10-3425

Application: AUDI A1 Sportback (8XA, 8XF) 1.4 TFSI Hatchback 2011 – 2015 185 / 136 CAVG, CTHG |

VKBA523 | 482A/472 | VKBA 5038 | 35BWD16 |

Company Profile

ZheJiang Mighty Machinery Co. Ltd is a professional manufacturer of auto bearings for more than 20 years. We provide a one-stop service for our customers. Our main products include wheel bearings & hub assembly, belt tensioners, clutch release bearings, and other parts.

Relying on the professional and rich manufacturing experience and many substantial factories which stable cooperated for many years, Mighty suppliers customers high-quality products at very competitive prices.

Customer’s satisfaction is our First Priority, We adhere to the concept of ” Quality First, Customer First”. We will continue to provide high-quality products and the best services to our customers and build up CZPT long-time friendship partners.

Our Advantages

More than 20 years of manufacturing and exporting experience

OEM manufacturing available

Full range, large stock

Quickly feedback

One year warranty

One-stop service

On-time delivery

Packaging & Shipping

FAQ

1. What’s the minimum order quantity?

We don’t have the minimum order quantity. We can also provide free samples, but you need to pay the freight.

2. Do you provide ODM&OEM order service?

Yes, we provide ODM&OEM services to customers around the world, and we can customize different brands and different sizes of pacakging boxes according to customers’ requirements.

3. After-sales service and warranty time

We guarantee that our products will be free from defects in materials and workmanship within 12 months from the date of delivery. The warranty is void due to improper use, incorrect installation, and physical damage.

4. How to place an order?

Send us an email of the models, brand, quantity, consignee information, model of transportation, and payment

Confirm payment and arrange the production.

5. What are your packing conditions?

We use standardized export packaging and environmental protection packaging materials. If you have a legally registered patent, we will package the goods in your brand box after receiving your authorization

6. What are your payment terms?

T/T is 30% of the payment in advance and 70% balance before delivery. Before you pay the balance, we will show you photos or videos of the products and packaging.

7. How long is your delivery time?

The delivery time of sample order is 3-5 days, and that of a batch order is 5-45 days. The exact delivery time depends on the item and the quantity you ordered.

8. Do you test all products before delivery?

Yes, according to ISO standards, we have professional Q/C personnel, precision testing instruments, and an internal inspection system. We control the quality of every process from material receiving to packaging to ensure that you receive high-quality products

Tips For Replacing a Belt Tensioner

When replacing a serpentine belt or automatic tensioner, you will need a special tool. This tool has a long, flat extension handle that allows you to place a socket onto the bolt and flats on the tensioner arm. The following are some tips to follow when replacing the belt or tensioner on your vehicle. To replace your belt or tensioner, you should start by checking the tensioner’s lubrication.

Serpentine belt

If you notice that the power steering or air conditioning are not working, you should check the serpentine belt tensioner. A malfunctioning serpentine belt tensioner can lead to a host of other issues. The belt may stretch, which can be caused by several factors. Over time, serpentine belt tensioners can also get worn down. Additionally, they can have a variety of other problems, including rust or dirt in the housing.

You can replace your serpentine belt by following the instructions found on your vehicle’s manual. Some tensioners attach to the engine via a single bolt. To remove and replace the belt, remove the old unit and the retaining bolt. Locate the locking pin in the engine and place the new tensioner over it. Use a torque wrench or hand tool to tighten the bolts. When installing the new tensioner, be sure to line up the mounting bolt holes with the mounting bolts. Once the tensioner is installed, test the tension by ensuring that the gauge is above the ribs. If it slides down, it is time to replace the tensioner.

Before you begin the process of replacing your serpentine belt, be sure to park your vehicle in a level area. Turn off the engine and chock both rear wheels before starting the process. Using a diagram from your vehicle’s repair manual can make the process easier, especially if you are a beginner. You can draw it in your hand, or refer to a repair manual to find out the exact location of the tensioner pulley.

If you notice that the belt is slipping or squealing while driving, it may be time to replace the serpentine belt tensioner. A worn-out belt can cause the belt to slip and can cause power steering, air conditioning, and alternator malfunctions. You should also check the belt tensioner regularly. The motor may stall or make a loud noise. These are all signs of worn-out serpentine belt.

A serpentine belt uses less space in the engine than a V-belt. It also provides more tension for the serpentine belt, which prevents it from running hot and squealing. Serpentine belts are manufactured to last for several hundred thousand miles. They are a must-have item for your car! So be sure to keep it maintained and properly adjusted! Then, you can be sure to have your car running smoothly and safely.

If you notice any of these symptoms, you should replace your serpentine belt tensioner. A serpentine belt tensioner is a simple self-10sioning device that is mounted on the front of the engine. These devices are usually easy to replace and are not complicated to install. You can find 1 at any parts store or online. When the time comes to replace your serpentine belt, don’t hesitate to get the parts you need from a local auto part store.

Idler pulley

The idler pulley and the belt tensioner are essential components of your car’s drivetrain. If any 1 of them fails, all of them must be replaced. This is because they were manufactured at the same time and most likely have the same number of miles on them. As a result, they can all fail within a few thousand miles of each other. Here are some of the symptoms that you should look for when inspecting your idler pulley or belt tensioner.

Idler pulleys are a common part of most cars. They play a vital role in the operation of the belt system by directing the belt’s path and providing additional contact with the pulley. The idler pulley is also responsible for turning the cooling fan in an air-cooled Corvair engine. Because of these functions, idler pulleys are often replaced with idlers that differ in size.

Idler pulleys are small, 2 to 4 inches in diameter and mounted on the front of the engine block. Their purpose is to create a constant amount of tension on the drive belt. When the idler pulley is worn out, the accessory drive belt may experience excessive vibration and squealing noises. You may wish to replace it as soon as possible. You can do so at AutoZone.

A worn or damaged idler pulley will require a replacement. The belt itself will not fall off the car unless the idler pulley is damaged. A squealing sound can be a sign of a broken spring. Alternatively, a mechanic can recommend a replacement based on the condition of the idler pulley. In most cases, idler pulleys are more durable than the belts and are therefore recommended for replacement.

You can also notice that the idler pulley is slipping or causing excessive noise. Its constant rotation wears the idler pulley and reduces the tension of the belt. This causes the belt to slip and may even tear off the engine. Ultimately, this could result in stalling. And if you notice the engine belt squealing or making excessive noises, you should consider replacing it.

An idler pulley for a belt tensioner are often confused. Though both of them are used in the same application, they differ in many ways. The tensioner is the 1 that receives pressure from the belts and moves them. The idler pulley is not attached to an adjustable bolt, and it can cause unusual noises. It might even make squealing or odd noises.

Spring tensioner

A spring belt tensioner is a solution to a loose belt. It features a strong torsion spring that reduces slack. These devices are designed to fit up to 6mm wide belts. They are highly reliable and durable. They are also suitable for applications where the engine speed is often fluctuating. Here’s how you can choose the best 1 for your vehicle. The spring in the tensioner should be in the proper position to keep the belt taut and free of slippage.

The RunRight tensioner is a durable, high-quality product that uses aluminum alloy. Its elastomeric inserts rely on highly elastic natural rubber for good shape memory and durability. Spring tensioners are easy to install and maintain. They are designed for both axial and helical drives. They feature detailed technical drawings and 3-D models to help you determine the best 1 for your application. To choose a spring tensioner, visit our website.

A worn bushing in the tensioner pulley or a loose pivot arm can result in excessive noise, vibration, and premature belt failure. In addition, worn springs cannot maintain proper tension. Over time, they lose tension. The pulley arm itself can also become damaged, preventing it from rotating properly. If these problems occur, you’ll need to replace the spring tensioner. If you don’t see any signs of wear, check your mounting bracket and tensioner.

A worn pivot bushing can cause the tensioner arm to misalign, leading to excessive back and forth sway. It may also cause the tensioner to jam, which means the belt is too long or too short. If you notice excessive wobble, you should replace the spring tensioner. A faulty tensioner may also be causing excessive oscillation in the pulley. To determine if the spring tensioner is too weak or jammed, check the belt’s length by using a breaker bar or socket with a long handle ratchet.

When it’s time to replace your serpentine belt, don’t forget to replace the belt tensioner. The tensioner protects other components from premature failure. It is a relatively inexpensive repair. It should be replaced as part of a larger multi-ribbed belt. It also provides protection for other components of the drive system. In addition to its protection and performance, the tensioner is inexpensive and relatively easy to replace.

It’s vital to check the tensioner and idler pulleys to make sure the system is aligned properly. If they don’t align, the belt will slip and cause premature wear. Alternatively, the tensioner may have too much tension, overloading the shaft bearings and causing premature failure in other parts. You should also check the idler pulleys for noise as well, since these are engine-driven accessories.

China high quality Oem MC824410 MC824411 MC824412 Drive Shaft Rubber Center Support Bearing for CZPT with Best Sales

OE NO.: MC824410 MC824411

Dimension: Oem common dimension

Content: Rubber

Guarantee: 3 Several years

Car Make: For Mitsubishi

Ekko quantity: EMN-0006999

Issue: New

Certification: ISO9001/TS16949

Sample: Availabe

MOQ: 50pcs

Transport: By categorical, by air, by sea

Shipping time: 1-7 Days for stock objects, ten-twenty five days for production purchase

Payment: T/T. 30% Deposit.Western Union

Quality: OEM Substantial

Item Title: Travel Shaft Rubber Centre Support Bearing for CZPT FUSO

Oem MC824410 MC824411 MC824412 Drive Shaft Rubber Centre Assist Bearing for CZPT FUSO

OEM:MC824410MC824411MC824412MC824413MC824414 For CZPT (FK415, FK515) eighty five- Our guarantee addresses merchandise delivered from us for period of 3 yearsWe will offer you you a free alternative for the faulty merchandise in your future orders.This warranty does not go over failures owing to: • Accident or collision.

• Incorrect set up.

• Transmission GearBox elements for chinese loader dozer XGMA SHXIHU (WEST LAKE) DIS.I SDL CZPT Misuse or abuse.

• Consequential damages owing to failure of other elements. • Elements utilised off-highway or for racing functions (until explicitly mentioned)

Related Merchandise

Business InfoEKKO is a skilled maker on automotive rubber components commenced from the yr 2003 Business are managered in accordance to ISO/TS16949 regular. Primary market place are United states,Europe,Latin America…ect We owned 6 creation lines with the ability of 8,000, M11 Higher Top quality Automated Transmission Gearbox Brake Band for Geely Ssangyong 000 pieces per year.

Packaging & ShippingPacking: Polybag, Netural box packing, Ekko shade box packing or Custom-made box packing Shipping and delivery Time : quick shipping for the items with inventory,new production merchandise: 30-forty five days

Our certifications

Our Exhibition

FAQone.What is your MOQ? We do not have MOQ . we settle for reduce amount for your demo order . For the product we have in inventory We can even provide you at 5pcs . 2. Can I get samples? Of system, we usually offer present sample for cost-free, nevertheless a small sample cost is necessary for custom styles. Sampls demand is refundable when purchase is up to a specific quantity. three. How prolonged is the lead time of the samples? For current samples, Factory Directly Higher High quality ul listed insulated grounding bushing it requires 3-5 times . four. How prolonged is the production direct time? For some itesm we hold some inventory that can be delived in 2 months. New poductioin leadtime sixty-80 times 5.What is your payment term? Reviewed! T/T / L/C /Paypal 6.Can I tailored my own Brand name Of course we can do nonetheless you need to have to reach specific quantity for every merchandise seven. Which varieties of Certification would you have? ISO/TS16949 eight. How will you deliver the items? For some orders with little quanity we can supply by air or express And for bulk and huge amount we will supply via CZPT by FCL or LCL.

Make contact with Us

Information to Generate Shafts and U-Joints

If you are concerned about the efficiency of your car’s driveshaft, you happen to be not by itself. Numerous vehicle owners are unaware of the warning signs of a unsuccessful driveshaft, but realizing what to look for can help you stay away from expensive repairs. Right here is a quick manual on generate shafts, U-joints and maintenance intervals. Shown below are key points to consider ahead of changing a motor vehicle driveshaft.

Indicators of Driveshaft Failure

Identifying a defective driveshaft is easy if you’ve got at any time listened to a odd noise from underneath your vehicle. These seems are brought on by worn U-joints and bearings supporting the travel shaft. When they fall short, the push shafts cease rotating appropriately, making a clanking or squeaking seem. When this happens, you might listen to sound from the aspect of the steering wheel or ground.

In addition to noise, a faulty driveshaft can trigger your auto to swerve in tight corners. It can also direct to suspended bindings that restrict general control. As a result, you should have these indicators checked by a mechanic as quickly as you observe them. If you observe any of the indicators previously mentioned, your next step need to be to tow your motor vehicle to a mechanic. To stay away from added difficulty, make confident you’ve taken precautions by examining your car’s oil degree.

In addition to these signs and symptoms, you must also search for any noise from the drive shaft. The initial point to search for is the squeak. This was induced by significant injury to the U-joint attached to the drive shaft. In addition to sound, you must also search for rust on the bearing cap seals. In excessive situations, your vehicle can even shudder when accelerating.

Vibration although driving can be an early warning indication of a driveshaft failure. Vibration can be due to worn bushings, trapped sliding yokes, or even springs or bent yokes. Abnormal torque can be triggered by a worn centre bearing or a ruined U-joint. The vehicle could make unusual noises in the chassis technique.

If you notice these indications, it’s time to consider your car to a mechanic. You need to verify frequently, especially large autos. If you might be not certain what is actually triggering the sound, check out your car’s transmission, engine, and rear differential. If you suspect that a driveshaft demands to be changed, a certified mechanic can exchange the driveshaft in your car.

Drive shaft kind

Driveshafts are employed in numerous different sorts of automobiles. These contain four-wheel drive, front-motor rear-wheel generate, bikes and boats. Every single type of generate shaft has its very own purpose. Underneath is an overview of the a few most widespread varieties of push shafts:

The driveshaft is a round, elongated shaft that transmits torque from the motor to the wheels. Push shafts often incorporate many joints to compensate for changes in size or angle. Some travel shafts also incorporate connecting shafts and interior continuous velocity joints. Some also incorporate torsional dampers, spline joints, and even prismatic joints. The most essential issue about the driveshaft is that it performs a important position in transmitting torque from the engine to the wheels.

The push shaft requirements to be equally light and robust to go torque. While metal is the most frequently utilized materials for automotive driveshafts, other materials these kinds of as aluminum, composites, and carbon fiber are also typically utilised. It all depends on the goal and dimension of the motor vehicle. Precision Manufacturing is a good supply for OEM products and OEM driveshafts. So when you might be seeking for a new driveshaft, preserve these variables in thoughts when acquiring.

Cardan joints are yet another common push shaft. A universal joint, also acknowledged as a U-joint, is a flexible coupling that makes it possible for one particular shaft to push the other at an angle. This kind of generate shaft permits electrical power to be transmitted even though the angle of the other shaft is continuously shifting. Whilst a gimbal is a good selection, it is not a ideal resolution for all apps.

CZPT, Inc. has condition-of-the-artwork equipment to provider all varieties of drive shafts, from tiny cars to race vehicles. They provide a assortment of needs, such as racing, market and agriculture. No matter whether you want a new generate shaft or a easy adjustment, the workers at CZPT can meet all your needs. You will be again on the highway before long!

U-joint

If your auto yoke or u-joint displays signs of dress in, it really is time to replace them. The least difficult way to change them is to comply with the steps below. Use a massive flathead screwdriver to take a look at. If you come to feel any motion, the U-joint is faulty. Also, inspect the bearing caps for harm or rust. If you can not uncover the u-joint wrench, consider examining with a flashlight.

When inspecting U-joints, make positive they are effectively lubricated and lubricated. If the joint is dry or improperly lubricated, it can swiftly fail and trigger your car to squeak although driving. Another signal that a joint is about to are unsuccessful is a sudden, extreme whine. Verify your u-joints every calendar year or so to make certain they are in suitable functioning buy.

Regardless of whether your u-joint is sealed or lubricated will count on the make and design of your car. When your automobile is off-street, you need to install lubricable U-joints for durability and longevity. A new driveshaft or derailleur will cost more than a U-joint. Also, if you do not have a great knowing of how to substitute them, you could want to do some transmission perform on your motor vehicle.

When replacing the U-joint on the push shaft, be sure to choose an OEM alternative every time possible. While you can very easily mend or substitute the original head, if the u-joint is not lubricated, you may need to have to replace it. A ruined gimbal joint can result in problems with your car’s transmission or other crucial components. Changing your car’s U-joint early can ensure its prolonged-time period functionality.

Another selection is to use two CV joints on the drive shaft. Using numerous CV joints on the generate shaft assists you in situations in which alignment is difficult or working angles do not match. This sort of driveshaft joint is more high-priced and sophisticated than a U-joint. The down sides of utilizing several CV joints are extra length, excess weight, and lowered functioning angle. There are several causes to use a U-joint on a generate shaft.

maintenance interval

Examining U-joints and slip joints is a vital component of schedule upkeep. Most autos are geared up with lube fittings on the driveshaft slip joint, which need to be checked and lubricated at each oil modify. CZPT technicians are nicely-versed in axles and can very easily determine a poor U-joint based on the sound of acceleration or shifting. If not fixed properly, the drive shaft can fall off, necessitating costly repairs.

Oil filters and oil alterations are other areas of a vehicle’s mechanical program. To prevent rust, the oil in these areas need to be changed. The identical goes for transmission. Your vehicle’s driveshaft must be inspected at the very least each 60,000 miles. The vehicle’s transmission and clutch must also be checked for dress in. Other components that must be checked contain PCV valves, oil traces and connections, spark plugs, tire bearings, steering gearboxes and brakes.

If your car has a guide transmission, it is ideal to have it serviced by CZPT’s East Lexington authorities. These providers must be performed each and every two to 4 several years or every 24,000 miles. For ideal results, refer to the owner’s handbook for recommended maintenance intervals. CZPT experts are knowledgeable in axles and differentials. Normal routine maintenance of your drivetrain will keep it in excellent working order.