Product Description

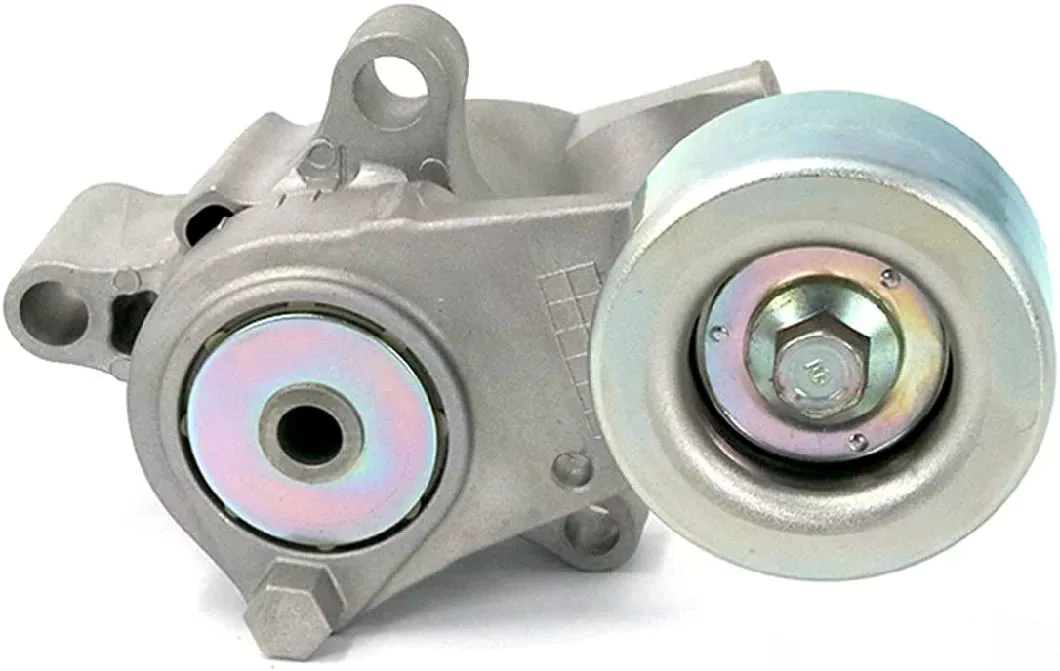

878016889 Tractor Belt Tensioner Ford

OEM: 878016889

Application:Tractor Belt Tensioner Ford

Tractor types: 5640, 6640, 7740, 7840, 8240, 8340

Product Parameters

|

OEM NO. |

878016889 |

| Tractor Type | Ford |

|

Place of Origin |

ZHangZhoug, China |

|

Material |

Aluminium |

| Product Name |

Tensioner |

|

Reference NO. |

|

|

Packing |

Neutral Packing |

|

SHIPPING TERM |

Sea/Air |

|

Quality |

100%tested |

|

Size |

same as OEM |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001, TS16949 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there specific considerations for choosing V-belt tensioners in applications with varying loads or environmental conditions?

When selecting V-belt tensioners for applications with varying loads or environmental conditions, several specific considerations should be taken into account. The performance and longevity of the tensioners can be greatly influenced by these factors, and choosing the right tensioner design and features is crucial. Here’s a detailed explanation of the considerations for choosing V-belt tensioners in applications with varying loads or environmental conditions:

- Load Capacity:

- Adjustability:

- Damping and Shock Absorption:

- Environmental Compatibility:

- Temperature Range:

- Contamination Resistance:

In applications with varying loads, it is essential to select V-belt tensioners that can accommodate the full range of load requirements. The tensioner should have a sufficient load capacity to handle the maximum load conditions without excessive deflection or wear. Considerations such as the tensioner’s structural strength, the choice of materials, and the design of the bearing system all play a role in determining the tensioner’s load capacity.

V-belt tensioners in applications with varying loads often require adjustability to maintain the appropriate tension as the load conditions change. Adjustable tensioners allow for fine-tuning of the belt tension to ensure optimal performance and prevent issues like belt slippage or excessive wear. Tensioners with adjustable features, such as movable brackets, sliding mechanisms, or threaded adjustments, provide flexibility to adapt to different load conditions and maintain proper belt tension.

In applications where loads are subject to sudden changes or shocks, it is important to consider the tensioner’s ability to absorb and dampen these dynamic forces. Tensioners with built-in damping or shock absorption mechanisms can help minimize the impact of sudden load fluctuations on the belt system. These features can include rubber or elastomeric components, hydraulic dampers, or spring-loaded systems that provide controlled movement and absorb the energy generated by load changes.

Environmental conditions can have a significant impact on the performance and longevity of V-belt tensioners. In applications with varying environmental conditions, it is crucial to choose tensioners that are compatible with the specific environment. Factors such as temperature extremes, moisture, dust, chemicals, or exposure to UV radiation should be considered. Tensioners with appropriate materials, coatings, and sealing mechanisms can offer improved resistance to corrosion, wear, and environmental degradation, ensuring reliable performance even in challenging conditions.

If the application involves extreme temperature variations, selecting V-belt tensioners that can withstand the temperature range is vital. High temperatures can affect the tensioner’s materials, lubrication, and sealing capabilities, leading to premature wear or failure. Tensioners designed for high-temperature applications may incorporate heat-resistant materials, special coatings, or cooling mechanisms to ensure reliable performance under elevated temperatures. Conversely, in low-temperature environments, tensioners with materials that maintain flexibility and lubrication systems suitable for low temperatures should be chosen.

In environments with high levels of contamination, such as dust, dirt, or debris, it is important to select V-belt tensioners that can resist the ingress of contaminants. Tensioners with effective sealing mechanisms, protective coatings, or features that prevent the accumulation of debris can help maintain proper functioning and extend the tensioner’s lifespan in such environments. Regular maintenance and cleaning procedures should also be considered to mitigate the negative effects of contamination.

Considering these specific factors when choosing V-belt tensioners for applications with varying loads or environmental conditions can help ensure optimal performance, longevity, and reliability of the tensioning system. By selecting tensioners with appropriate load capacity, adjustability, damping capabilities, environmental compatibility, temperature resistance, and contamination resistance, the risk of premature failure or performance issues can be minimized, contributing to the overall efficiency and effectiveness of the V-belt system.

Can you provide examples of products or machinery that rely on V-belt tensioners for efficient operation?

There are numerous products and machinery across various industries that rely on V-belt tensioners for efficient operation. V-belt tensioners play a crucial role in maintaining proper belt tension, preventing slippage, and ensuring optimal power transmission. Here are some examples of products and machinery that commonly utilize V-belt tensioners:

- Automotive Engines:

- Industrial Machinery:

- HVAC Systems:

- Agricultural Equipment:

- Construction and Mining Equipment:

- Power Generation Systems:

- Food Processing Machinery:

In automotive engines, V-belt tensioners are essential for driving components such as the alternator, water pump, power steering pump, and air conditioning compressor. These tensioners help maintain proper belt tension, ensuring efficient power transfer and reliable operation of these critical engine accessories.

V-belt tensioners are widely used in various industrial machinery, including conveyors, pumps, compressors, fans, and blowers. These tensioners ensure optimal power transmission, prevent belt slippage, and maintain consistent performance in industrial applications.

Heating, ventilation, and air conditioning (HVAC) systems rely on V-belt tensioners to drive components such as fans, blowers, and air handling units. Proper tensioning of V-belts in these systems ensures efficient airflow, reliable operation, and optimal performance, contributing to effective temperature control in residential, commercial, and industrial settings.

Agricultural machinery, such as tractors, harvesters, irrigation pumps, and grain conveyors, often incorporate V-belt tensioners. These tensioners play a vital role in power transmission, ensuring reliable operation and maximizing productivity in agricultural processes.

V-belt tensioners are commonly used in construction and mining equipment, including excavators, bulldozers, loaders, and crushers. These tensioners help drive essential components such as hydraulic pumps, generators, and conveyors, ensuring efficient power transmission and reliable performance in demanding construction and mining operations.

V-belt tensioners are frequently used in power generation systems, including generators and turbines. These tensioners help drive auxiliary components such as cooling fans, pumps, and alternators, ensuring reliable power transmission and optimal functionality in power generation plants.

In the food processing industry, V-belt tensioners are commonly employed in machinery used for food production, packaging, and processing. They are used in equipment such as mixers, conveyors, blenders, slicers, and food processors. V-belt tensioners ensure reliable power transmission, consistent operation, and adherence to hygiene standards in food processing facilities.

These are just a few examples of the wide range of products and machinery that rely on V-belt tensioners for efficient operation. V-belt tensioners are utilized in numerous other industries and applications where V-belts are used for power transmission. Their critical role in maintaining optimal belt functionality makes them an integral component in various systems that require reliable and efficient power transfer.

Are there specific designs of V-belt tensioners for different applications, like automotive or industrial equipment?

Yes, there are specific designs of V-belt tensioners tailored for different applications, such as automotive or industrial equipment. The designs of V-belt tensioners are often optimized to meet the specific requirements and challenges of different industries and machinery. Here’s a detailed explanation:

- Automotive Applications:

- Industrial Equipment:

- HVAC Systems:

- Agricultural Machinery:

- Construction and Mining Equipment:

- Industry-Specific Applications:

In the automotive industry, V-belt tensioners are designed to meet the unique demands of automotive engines. Automotive tensioner designs often incorporate features that address factors such as limited space, high vibration, and exposure to extreme temperatures. These tensioners are typically compact and durable, ensuring reliable operation in the demanding automotive environment. They may also incorporate additional features like built-in damping mechanisms to reduce noise and vibration.

For industrial equipment, V-belt tensioners are designed to withstand the rigorous conditions typically encountered in industrial settings. These tensioners are often built with heavy-duty materials and robust construction to handle high loads and prolonged operation. They may include features like sealed bearings or protective covers to prevent contamination from dust, dirt, or debris. Industrial tensioner designs prioritize durability, longevity, and consistent performance in demanding industrial applications.

V-belt tensioners used in HVAC systems are designed to meet the specific requirements of heating, ventilation, and air conditioning equipment. These tensioners often prioritize quiet operation, as noise reduction is crucial in HVAC applications. They may incorporate features like low-friction materials or noise-dampening mechanisms to minimize belt noise. HVAC tensioner designs also consider space limitations and ease of installation and maintenance in HVAC equipment.

In agricultural machinery, V-belt tensioners are designed to withstand the harsh conditions of farming operations. These tensioners may have additional protection against environmental factors such as dust, moisture, and agricultural chemicals. Agricultural tensioner designs often prioritize ease of adjustment and maintenance, as these machines may require frequent belt changes or tension adjustments in the field.

V-belt tensioners used in construction and mining equipment are designed to handle heavy loads, shocks, and vibrations commonly encountered in these industries. These tensioners may have reinforced components and advanced sealing to withstand the rugged conditions of construction sites or mining operations. They are often designed with ease of installation and maintenance in mind, considering the challenging environments in which they are used.

In addition to the above examples, there are industry-specific V-belt tensioner designs tailored for particular applications. For example, tensioners used in the printing and paper industries may have features to minimize belt slippage and ensure precise registration of printing materials. Tensioners used in food processing machinery may have hygienic design features to meet sanitation requirements. Textile machinery may incorporate tensioners designed for high-speed operation and accurate tension control of drive belts.

Overall, V-belt tensioner designs are customized to address the specific needs, challenges, and operating conditions of different industries and machinery. These designs aim to optimize belt functionality, ensure reliable power transmission, and enhance the overall performance of the equipment in which they are employed.

editor by CX 2024-03-27

China Good quality F1nn6b209AA for CZPT Tractor Tensioner Pulley, V-Ribbed Belt cv axle replacement cost

Product Description

F1NN6B209AA CZPT Tractor Tensioner Pulley, v-ribbed belt

OEM:F1NN6B209AA

APPLICATION: NEW HOLLAND

Product Parameters

|

OEM NO. |

F1NN6B209AA |

| Application | NEW HOLLAND |

|

Place of Origin |

ZHangZhoug, China |

|

Material |

Aluminium |

| Product Name | Belt tensioner |

|

Reference NO. |

|

|

Packing |

Neutral Packing |

|

SHIPPING TERM |

Sea/Air |

|

Quality |

100%tested |

|

Size |

same as OEM |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001, TS16949 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you describe the various mounting options and installations for V-belt tensioners in different settings?

When it comes to mounting V-belt tensioners, several options and installations are available to accommodate different settings and applications. The choice of mounting method depends on factors such as space constraints, accessibility, system design, and the specific requirements of the V-belt system. Here’s a detailed description of the various mounting options and installations for V-belt tensioners:

- Bolt-On Mounting:

- Weld-On Mounting:

- Stud-Mounted:

- Spring-Loaded Tensioners:

- Hydraulic Tensioners:

- Automatic Tensioners:

Bolt-on mounting is a common method used to install V-belt tensioners. In this configuration, the tensioner is equipped with mounting holes or brackets that align with corresponding holes on the mounting surface. The tensioner is secured in place using bolts or screws. Bolt-on mounting provides a sturdy and reliable installation, allowing for easy adjustment and maintenance when needed. It is commonly used in industrial machinery, automotive applications, and other settings where the tensioner needs to be securely mounted.

Weld-on mounting involves permanently attaching the tensioner to the mounting surface by welding. This method is often used in heavy-duty applications or settings where additional strength and stability are required. Weld-on mounting provides a secure and rigid installation, ensuring that the tensioner remains in place even under high loads or vibrations. It is commonly used in construction equipment, agricultural machinery, and other demanding environments.

Stud-mounted tensioners feature a threaded stud that is welded or attached to the mounting surface. The tensioner can then be threaded onto the stud and secured in place using a nut or locking mechanism. Stud-mounted tensioners offer a flexible and adjustable installation, allowing for easy tension adjustment and replacement. They are commonly used in applications where frequent tension adjustments or belt changes are required, such as conveyor systems or woodworking machinery.

Spring-loaded tensioners are designed with a built-in spring mechanism that applies constant tension to the V-belt. These tensioners often have a base plate or bracket that can be bolted or welded onto the mounting surface. The spring-loaded tensioner is then attached to the base plate or bracket and adjusted to the desired tension. Spring-loaded tensioners are commonly used in automotive engines, HVAC systems, and other applications where maintaining consistent belt tension is crucial.

Hydraulic tensioners rely on hydraulic pressure to maintain proper belt tension. These tensioners are typically mounted using bolt-on or stud-mounted configurations. They feature an adjustable hydraulic cylinder that applies the desired tension to the V-belt. The hydraulic tensioner is mounted securely, and the hydraulic pressure is adjusted to achieve the correct tension. Hydraulic tensioners are commonly used in industrial machinery, heavy equipment, and power transmission systems.

Automatic tensioners use a combination of mechanical, hydraulic, or electronic mechanisms to adjust and maintain the tension of the V-belt automatically. The mounting options for automatic tensioners can vary depending on the specific design and manufacturer. They may utilize bolt-on, weld-on, or stud-mounted configurations. The installation process typically involves securing the tensioner in the desired position and connecting it to the V-belt system. Automatic tensioners are commonly used in automotive engines, industrial equipment, and other applications where continuous tension adjustment is required.

These various mounting options and installations for V-belt tensioners provide flexibility to accommodate different settings and applications. Whether it’s bolt-on mounting, weld-on mounting, stud-mounted configurations, or specific designs like spring-loaded, hydraulic, or automatic tensioners, selecting the appropriate mounting method ensures a secure and effective installation of the tensioner in the V-belt system.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a critical role in reducing wear and increasing the efficiency of power transmission in V-belt systems. They help maintain proper belt tension, ensuring optimal grip between the belt and pulleys. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Maintaining Proper Belt Tension:

- Optimizing Belt Grip:

- Reducing Belt Slippage:

- Promoting Even Load Distribution:

- Minimizing Belt Vibrations:

V-belt tensioners are designed to apply and maintain the correct tension in V-belt systems. When the tension is too loose, the belt can slip on the pulleys, leading to increased wear on the belt and reduced power transmission efficiency. Conversely, when the tension is too tight, excessive stress is placed on the belt and other system components, resulting in accelerated wear. V-belt tensioners ensure the optimal tension level, preventing slippage and excessive stress, and minimizing wear.

Proper tensioning of V-belts ensures optimal grip between the belt and pulleys. The tensioner maintains the desired tension, which allows the belt to effectively engage the pulley grooves. This optimal grip ensures efficient power transmission, as the friction between the belt and pulleys enables the transfer of rotational force. By maximizing belt grip, V-belt tensioners minimize power losses due to slippage, enhancing the overall efficiency of power transmission.

One of the main causes of wear in V-belt systems is belt slippage. Slippage occurs when the belt loses traction with the pulleys, resulting in a loss of power transmission efficiency and increased wear on the belt. V-belt tensioners help prevent slippage by maintaining the proper tension, which ensures that the belt remains securely engaged with the pulleys. By reducing belt slippage, V-belt tensioners minimize wear on the belt and other components, improving the overall system efficiency.

Proper tensioning of V-belts helps promote even load distribution across the belt and pulleys. When the tension is correctly set, the load is evenly distributed along the width of the belt, minimizing localized stress points. This even load distribution reduces wear on specific areas of the belt, prolonging its lifespan. Additionally, by evenly distributing the load, V-belt tensioners help prevent premature wear on the pulleys and other components, contributing to increased system efficiency.

Improperly tensioned V-belts can induce vibrations during operation, leading to increased wear and reduced power transmission efficiency. V-belt tensioners help minimize belt vibrations by maintaining the correct tension, ensuring a stable and secure operation. By reducing belt vibrations, V-belt tensioners contribute to decreased wear on the belt and other system components, improving power transmission efficiency.

In summary, V-belt tensioners contribute to reducing wear and increasing power transmission efficiency by maintaining proper belt tension, optimizing belt grip, reducing belt slippage, promoting even load distribution, and minimizing belt vibrations. These factors collectively ensure efficient power transfer, reduce wear on the belt and other system components, and enhance the overall performance and longevity of V-belt systems.

In what industries and machinery are V-belt tensioners commonly used for optimal belt functionality?

V-belt tensioners are commonly used in various industries and machinery to ensure optimal belt functionality. Here’s a detailed explanation of the industries and machinery where V-belt tensioners are frequently employed:

- Automotive Industry:

- Industrial Manufacturing:

- HVAC Systems:

- Agricultural Equipment:

- Construction and Mining:

- Power Generation:

- Food Processing:

In the automotive industry, V-belt tensioners are extensively used in engines to drive multiple components, such as the alternator, water pump, power steering pump, and air conditioning compressor. These tensioners help maintain proper belt tension, ensuring efficient power transmission and reliable operation of these critical engine accessories.

V-belt tensioners find wide application in various industrial manufacturing processes. They are commonly used in machinery such as conveyors, pumps, compressors, fans, and blowers. These tensioners ensure optimal power transmission, prevent belt slippage, and maintain consistent performance in these industrial applications.

Heating, ventilation, and air conditioning (HVAC) systems rely on V-belt tensioners to drive components such as fans, blowers, and air handling units. Proper tensioning of V-belts in these systems ensures efficient airflow, reliable operation, and optimal performance, contributing to effective temperature control in residential, commercial, and industrial settings.

In the agricultural sector, V-belt tensioners are commonly utilized in various machinery, including tractors, harvesters, irrigation pumps, and grain conveyors. These tensioners play a vital role in power transmission, ensuring reliable operation and maximizing productivity in agricultural processes.

Construction and mining equipment, such as excavators, bulldozers, loaders, and crushers, often incorporate V-belt tensioners. These tensioners help drive essential components, such as hydraulic pumps, generators, and conveyors, ensuring efficient power transmission and reliable performance in demanding construction and mining operations.

V-belt tensioners are frequently used in power generation systems, including generators and turbines. These tensioners help drive auxiliary components, such as cooling fans, pumps, and alternators, ensuring reliable power transmission and optimal functionality in power generation plants.

In the food processing industry, V-belt tensioners are commonly employed in machinery used for food production, packaging, and processing. They are used in equipment such as mixers, conveyors, blenders, slicers, and food processors. V-belt tensioners ensure reliable power transmission, consistent operation, and adherence to hygiene standards in food processing facilities.

V-belt tensioners are also used in various other industries and machinery where V-belts are employed for power transmission. Some additional examples include marine applications, material handling equipment, printing and paper industries, textile machinery, and woodworking equipment. The versatility and effectiveness of V-belt tensioners make them a popular choice for ensuring optimal belt functionality across a wide range of industries and machinery.

editor by CX 2024-03-05

China Mtd 756-05034A Lawn Tractor Deck Flat Idler Pulley pulley drive

Solution Description

Description: #eastarsmallenginerepair

Deck Loafer Rebuild Established for Cub Cadet MTD Troy Bilt RZT XT1 50 fifty four TB2246 Horse CZPT Replaces 756-05034 756-05034A

· Flat Loafer Pulley Replaces MTD portion# 756-05034, 756-05034A

· Flat Loafer Pulley Fits for Types # Troy Bilt TB WC28, Mustang XP 46, Mustang XP Pivot S 46, Mustang Z42, CZPT 42 46, Horse 42, Horse XP, Mustang XP 50, Mustang XP 54, Mustang XP Pivot S 54, Pony, Super CZPT forty two, Super CZPT forty six, Tremendous CZPT fifty, Super CZPT fifty XP, Super CZPT fifty four, Super CZPT GT fifty four, TB1942, TB2246, TB2350, TB2454, TB42, TB46

· Fits for MTD Component # M200-46, Z510, Z530, Z550, Z6400, ZTS46, CGT5426, CLT42, CLT46CVT, CSLT5424, CYT4220, CYT4622SE, CYT5571SE, G8200, G8300, G8400, G8600, LT4200, LT4600, M115-42, T1000, T105, T110, T1100, T1200, T130, T1300, T135, T1400, T150, T1500, T1600, T1700, T1800, T1900, T210, T2100, T225, T240, T260, T2600, T2700, T2800, T3000, T310, T3100, T3200, T7800, T8000, T8200, T8400, T8600, Z560, Z6600, Z6900, ZS6700, ZTL50, ZTL54, ZT-S54

· Fits for Cub Cadet Element # CC 600, RZT-L34, RZT-L46, RZT-LX forty six, RZT-S46, RZT-SX forty six, ZT1-forty two, ZT1-46, ZT2-50, ZT2-sixty, LGT1050, LGTX1050, LTX1050, RZT LX 50, RZT-L50, RZT-L54, RZT-LX fifty, RZT-LX fifty four, RZT-S50, RZT-S54, RZT-SX fifty, RZT-SX 54, RZT-SX54, XT1-GT50, XT1- GT54, XT1-LT42, XT1-LT46, XT1-LT50, XT1-LT54, XT1-ST54, XT2-GX50, XT2-GX54, XT2-LX42, XT2-LX46, XT2-LX50, XT2-LX54, XT2-SLX50, XT2-SLX54, XT2-ST54, ZT1-50, ZT1-fifty four, ZT2-54

| ID | 17mm” |

| OD | 5-1/4″ |

| Peak | one-5/sixteen” |

| Content | Metal |

|

US $2.99-3.99 / Piece | |

5,000 Pieces (Min. Order) |

###

| Certification: | RoHS, CE, ISO, CCC |

|---|---|

| Power Source: | Gasoline |

| Type: | Deck Part |

| Material: | Carbon Steel |

| Od: | 4-1/2" |

| Usage: | Idler Pulley |

###

| Customization: |

Available

|

|---|

###

| ID | 17mm" |

| OD | 5-1/4" |

| Height | 1-5/16" |

| Material | Metal |

|

US $2.99-3.99 / Piece | |

5,000 Pieces (Min. Order) |

###

| Certification: | RoHS, CE, ISO, CCC |

|---|---|

| Power Source: | Gasoline |

| Type: | Deck Part |

| Material: | Carbon Steel |

| Od: | 4-1/2" |

| Usage: | Idler Pulley |

###

| Customization: |

Available

|

|---|

###

| ID | 17mm" |

| OD | 5-1/4" |

| Height | 1-5/16" |

| Material | Metal |

The Mechanical Advantage of a Pulley

A pulley is an important tool for many tasks. The advantage that it offers over a hand-held mechanism is its mechanical advantage. In this article, we’ll discuss the types of pulleys and their applications. We’ll also look at the types of compound pulleys. And, of course, there’s a little bit about the mechanical advantage of a pulley. This article will help you decide whether this tool is right for your needs.

Mechanical advantage of a pulley

A pulley has a mechanical advantage over a lever because it is able to produce more force over longer distances. The mechanical advantage of a pulley sounds brilliant and could produce energy. But what exactly is this mechanical advantage? Let’s take a look. First, consider how a pulley works. A rope supports a 100kg mass, which requires 500 newtons of force to lift. If the rope supports a 100kg mass, two sections of rope can support that load. Using a pulley, you can lift the same weight with half the force.

A pulley’s ideal mechanical advantage is the ratio of the force applied to the total length of the rope. The larger the radius, the greater the mechanical advantage. A pulley made up of four rope segments has an ideal mechanical advantage of four. Therefore, a four-segment pulley would multiply the force applied by four. As the numbers on the rope segments are smaller than the total length of the rope, it would be better to use a compound pulley.

The mechanical advantage of a pulley can be calculated by using the T-method. The first step in calculating the mechanical advantage of a pulley is defining the force you need to lift. Then, divide that force by two to calculate the amount of force you need to lift the load. Once you know this amount, you can design a pulley to meet your needs. That way, you can achieve the perfect balance between the two types of pulleys.

Types of pulleys

The main function of the pulley is to change the direction of the force. The mechanical advantages of a single pulley are two. Ideally, two pulleys should have two or more mechanical advantages. The mechanical advantage of compound pulleys can be increased to two or more. The number of pulleys that make up the composite pulley will determine the mechanical advantage. Certain types of pulleys are combined in one housing.

A stepped pulley is a set of pulleys with stepped surfaces. Each face is anchored to the mid-axis in an ordered sequence. This design gives these pulleys their name. They are used to increase and decrease the speed of the driven pulley. Step pulleys are usually used in pairs. They can be straight or stepped, but usually come in pairs.

The three main types of pulleys are pulleys, rope pulleys, and chain pulleys. Pulley Pulley systems use mechanics to lift and lower heavy objects. The Greek historian Plutarch credits the invention of the pulley to Archimedes of ancient Sicily. The Mesopotamians used rope pulleys to lift water around 1500 BC, and Stonehenge is said to have been built using a rope pulley system.

Application of pulley system

The advantages of using a pulley system are numerous. The ability to lift heavy objects is a good example. The pulley system makes it easy for people to lift blocks and other large objects. It can be used in many different applications, from utility elevators to construction cranes. In addition, it is widely used on sailing boats. If you want to learn more about the benefits of a pulley system, keep reading!

You can use the pulley system to water flowers or water plants. Some of them even lowered the pot to make cleaning easier. Pendant lights are another great place to install a pulley system. Climbing and fishing are just some of the activities that utilize the pulley. They are great for fishing and gardening. And since they are so versatile, you can use the pulley system anywhere.

To get the most out of your pulley system, you must choose a product that has all of the above attributes. A high-quality pulley must have a large pulley diameter and be made of sturdy materials. The cables must also be properly supported in the pulleys to ensure a long service life for your investment. A good cable should have minimal cracks and be lubricated. These factors are the most important considerations when choosing a pulley system for your needs.

composite pulley

Composite pulley systems combine two or more movable pulleys. These systems maximize the force to move the weight and can also change direction so they can be used to lift weights. Composite pulley systems can be as simple or as complex as your needs. For example, a pulley pulley system uses multiple pulleys on each axis. This method is often used for hoisting building materials.

A compound pulley system has two or more rope segments, each of which is pulled up on a load. It can increase lift by making objects move faster. These systems are common on large sailboats and construction sites. Composite pulleys are also available for larger boats. Due to their versatility, they are versatile tools for construction sites and large sailboats. If you have their app, you should consider buying one.

The main advantage of composite pulleys is their versatility. You can use them to lift weights or use them to save energy. Composite pulleys are especially useful for lifting heavy objects. For example, you can tie a paper clip to the end of the rope and pull it up. The flag is then lifted into the air with the help of compound pulleys. Composite pulleys are a great invention and they are often used in construction.

security considerations

There are several safety considerations to consider when using pulleys. The first is Secure Workload (SWL). This value is a general guideline for the maximum weight a pulley can safely handle. It varies according to the height and angle of the pulley. Besides SWL, there are some other factors to consider. Consider each one before deciding on the pulley that best suits your needs.

Another safety consideration is the weight of the load. Since the highs of the pulley are higher than the lows, it doubles in weight. The weight of the high point should not exceed 4 kN. The safety factor is calculated by multiplying the strength of the pulley by the weight of the load. Secondary COD has a safety factor of 10:1 and bulletproof primary anchors should be used with pulleys.

If using a chain hoist, you must be trained in the appropriate type of lifting. It is important not to hang on the top hooks of the structure, nor to overload or rig the hooks with multiple slings. You should also avoid corroded or damaged chains, as they can cause the crane to jam or overload. A worn chain can even cause the load to drop.

Components of a pulley system

Proper design of the pulley system can increase the life of the cables and pulleys. Larger diameter cables should be selected as they are more durable than smaller diameter cables. The cables should also be supported in the pulley grooves. The pulley must be designed to be compatible with the cable and its lubrication should be optimal. Proper lubrication of cables and pulleys will ensure maximum durability and longevity.

The first type of pulley is called a fast pulley. These pulleys are used for quick start and stop of the machine. These pulleys are usually mounted in pairs on the countershaft of the machine. One pulley is tightly mounted on the machine shaft, while the other pulley is fitted with a free-spinning mechanism. When the machine is running, the belt is mounted on the tensioner pulley, and when it is stopped, the belt slides on the independent pulley.

Composite pulley sets reduce the overall effort required by reducing the size of the pulley. These are usually attributed to Archimedes. Flat pulleys are often used in flat belt driven transmission systems. These are used in high-speed, low-power applications. Flat pulley idlers are also used on the back of traditional V-belts.

editor by czh 2023-01-05

China high quality Alternator Belt Tensioner 8149855 Tensioner for Renault Tractor Trucks and CZPT for CZPT D12 Engine 20966526 near me shop

Product Description

Product spections :

| RENAULT TRUCKS | 745719855 |

| VOLVO | 21422767 |

| VOLVO | 257160 |

| VOLVO | 2571523 |

| VOLVO | 8149855 |

| VOLVO | 20966526 |

| VOLVO | 2145718 |

Description :

1. The tensioner is a belt tensioner used in the automobile transmission system. The tension pulley is mainly composed of a fixed shell, a tension arm, a wheel body, a torsion spring, a rolling bearing and a spring sleeve. It can automatically adjust the tension force according to the different tightness of the belt to make the transmission system stable, safe and reliable.

2. The main function of the tensioner bearing is to support the mechanical rotating body.

3.Reduce the friction coefficient during its movement and ensure its rotation accuracy.

4.Change sliding friction into rolling friction.

| 2019 | Volvo | VNL | Base Straight Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2018 | Volvo | VNL | Base Straight Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2017 | Volvo | VNL | Base Straight Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2017 | Volvo | VNL | Base Tractor Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2016 | Volvo | VNL | Base Straight Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2016 | Volvo | VNL | Base Tractor Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2015 | Volvo | VNL | Base Straight Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2015 | Volvo | VNL | Base Tractor Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2014 | Volvo | VNL | Base Straight Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2014 | Volvo | VNL | Base Tractor Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2013 | Volvo | VNL | Base Straight Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2013 | Volvo | VNL | Base Tractor Truck – Long Conventional | 11.9L 726Cu. In. 6 CNG | |

| 2009 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2009 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2009 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2008 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2008 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2008 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2008 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2008 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL |

| 2007 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2007 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2007 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2007 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2007 | Volvo | VNM | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2007 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2006 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2006 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2006 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2006 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2006 | Volvo | VNM | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2006 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2005 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2005 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2005 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2005 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2005 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2004 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2004 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2004 | Volvo | VN | VN42T Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL |

| 2004 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2004 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2004 | Volvo | VNM | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2004 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2003 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2003 | Volvo | VHD | Base Straight Truck – Low Tilt | 12.1L 740Cu. In. 6 DIESEL | |

| 2003 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2003 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2003 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2003 | Volvo | VNM | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2003 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2002 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2002 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2002 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2002 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2002 | Volvo | VNM | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2002 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2001 | Volvo | VHD | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2001 | Volvo | VHD | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2001 | Volvo | VNL | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL |

| 2001 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2001 | Volvo | VNM | Base Straight Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2001 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2000 | Volvo | VNL | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 2000 | Volvo | VNM | Base Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 1999 | Volvo | VN | VN42T Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 1999 | Volvo | VN | VN64T Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 1998 | Volvo | VN | VN42T Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL | |

| 1998 | Volvo | VN | VN64T Tractor Truck – Long Conventional | 12.1L 740Cu. In. 6 DIESEL |

How to Repair a Timing Belt Tensioner

Your timing belt tensioner is a critical component of your vehicle’s drivetrain. Too little tension, for example, will cause the belt to slip, and too much tension can overload shaft bearings, leading to premature failure. If you notice that your belt tensioner is not working properly, you should immediately visit a mechanic. Corrosion from road splash, dirt, mud, or other debris can jam the tensioner housing. To avoid this, make sure that you replace your timing belt tensioner as soon as possible.

Symptoms of a bad belt tensioner

If you’ve ever wondered what signs indicate a bad belt tensioner, look no further than your vehicle’s engine. Worn belts or a broken tensioner can cause an irritating squealing noise, as well as the belt to slip. Even worse, a bad tensioner can cause water to enter the belt and pulley, resulting in water damage. A worn tensioner is usually the culprit of the noise, but there are also other warning signs that a belt is in trouble.

Your vehicle’s engine may start to run poorly or even squeal when you turn the key. Similarly, your engine may fail to start at all, or the check engine light may illuminate. The belt may also start to wear out in an unusual pattern. These signs indicate that the tensioner is in need of replacement. If you notice 1 or more of these signs, get your car checked right away.

To check the condition of the tensioner, remove the drive belt and observe the pulley. You may notice rust dripping or bleeding at the mounting bolts, which are the most common signs of a bad tensioner. If you can’t remove the drive belt, check the pulley by rotating it. If you feel resistance, the pulley is likely worn or slack.

Failure of the belt tensioner will also cause other parts of the car to fail. If a bad belt tensioner isn’t fixed quickly, you might not be able to use the vehicle properly. You could end up breaking your car’s engine, losing power steering, and possibly even the water pump. If your car is not running right, you could be stuck in the middle of nowhere. Even if the alternator doesn’t work, you’ll still have a malfunctioning power steering system and a dead AC system.

A broken timing belt tensioner can cause strange noises or a no-start condition. These noises and symptoms are signs of a bad belt tensioner, and you’ll have to replace it ASAP. If you don’t know what symptoms mean, don’t hesitate to take your car to a mechanic. You’ll be surprised how easy it is to check this vital component and save yourself a bunch of money.

Components of a belt tensioner

The components of a belt tensioner assembly consist of 4 key components. The clearance between the pulley and the base is critical to the tensioner’s operation. If the tensioner is installed incorrectly, the spring can break and cause severe injury. The spring’s preload and powerful force make it difficult to service the unit safely. These parts are non-serviceable. If you are unsure of how to repair your tensioner, contact an authorized mechanic.

The components of a belt tensioner drive are shown in FIG. 2. The rotor shaft is connected to the drive screw, while the second transmission is connected to the gear shaft. The rotor and gear shaft are in parallel with each other. The gear shaft and worm wheel are connected to the belt tensioner drive. In other words, the belt tensioner drive is located in the B-pillar of the motor vehicle.

A belt tensioner may be equipped with a drive shaft and electric motor. The drive shaft may also contain a worm gear or worm wheel. The drive shaft also has an intermediate gearbox. Once the tensioner is set, it is ready to move to its safe-position position. It is a relatively simple and inexpensive replacement for your belt. When replacing a multi-ribbed belt, be sure to replace the tensioner along with the belt. Gates recommends replacing all wear parts at once.

In the event of a faulty drive belt tensioner, the belt will not stay taut. The pulley can wobble and cause the belt to fray. In addition to this, the bearings can cause a loud squealing noise. In this case, the accessory motors will continue to run, while the belt itself will not. Therefore, replacing the timing belt tensioner is an important part of maintaining the car.

In some systems, the belt tensioner uses a worm gear as the first gear. This results in rolling engagement of the screw’s teeth. This reduces noise and vibrations, while maximizing the efficiency of the belt tensioner drive. Additionally, a worm gear can eliminate the need for additional parts in belt tensioners. While this may not be practical in all instances, it is a good choice for space-constrained environments.

Repair options for a timing belt tensioner

A timing belt tensioner is an essential part of an automobile’s timing chain and is responsible for ensuring proper timing. Proper alignment of timing marks is essential to the proper operation of the engine, and improper alignment may lead to damage to the engine. To repair a timing belt tensioner, there are several repair options available. First, you need to remove the engine cover. You can then remove the timing belt tensioner by loosening the pulley using a ratchet or breaker bar.

When the timing belt isn’t properly tensioned, the engine will misfire. The engine misfires when the valve opens and the pistons rise at the wrong time. When this happens, the timing belt cannot properly grip the gears and the engine will not function. If this part fails, you’ll have to replace the whole timing chain. However, if you are handy with tools, you can easily replace the entire timing belt tensioner yourself.

If your timing belt tensioner is out of alignment, you should replace it. If you’re not sure whether it needs to be replaced, check it with a professional and learn the details of the repair. The timing belt tensioner is the most critical part of the engine, so it’s important to know about it. Otherwise, your car won’t run as well as it could. Repair options for a timing belt tensioner will vary depending on the severity of the problem and how much damage it has done.

While there are several repair options for a timing belt tensioner, the average cost of replacement is $364 to $457, and this doesn’t take into account any tax or fee you may be charged. DIY repair methods will usually cost you $50 to $150, and you’ll likely save a lot of money in the process. However, you need to remember that you may be unable to do the job yourself because you don’t know how to use the proper tools and equipment.

While it is not difficult to replace a timing belt tensioner on your own, you should know that you’ll need to remove other parts of the engine as well as special tools to make the repair properly. This is an advanced repair job and requires a great deal of skill. If you’re new to home car repair, you may not want to attempt it yourself. There are many other options, such as hiring a mechanic.

Installation instructions

While there are no universal installation instructions for belt tensioners, the manufacturer of your car may provide detailed instructions. Before attempting to replace your tensioner, read the manufacturer’s recommended procedures carefully. To install a new tensioner properly, unload the old 1 and take a picture or sketch of how the belt should be routed. Once the old tensioner is out, follow the manufacturer’s torque specifications. Make sure to unload and remove the belt from the tensioner, and follow the manufacturer’s torque specifications to install the new one.

If your car comes with a manual belt tensioner, you can follow the instructions. The manual will have a corresponding guide for installation. When installing a belt tensioner, make sure the manual clearly states the static tension for your particular model. Check that it is in line with the engine relief to ensure proper belt tension. You can then use a 6mm allen key to turn the tensioner clockwise and counterclockwise. Once it is in position, release the tensioner to operate. The belt tensioner should now apply the proper tension to your belt.

Before installing a new belt tensioner, make sure you read the manual completely. You should follow these steps carefully to avoid any problems with the tensioner. If the tensioner has failed, you must replace it immediately. A new belt tensioner will help you ensure proper performance of your accessory belt drive system. If you are installing a new multi-ribbed belt, you should replace the tensioner as well. However, it is important to note that replacing the belt tensioner is a complicated process and requires a mechanic to be able to safely remove the belt from the engine.

To install a second stage drive belt, walk the belt onto the input drive and generator. Ensure that the belt is seated properly in the grooves of the pulleys. Next, replace the input drive belt and right and left Drive Disk covers. Test the machine to ensure that it is working properly. If it doesn’t, replace the original drive belt. After installing the new belt, you may want to read the manual again to make sure it is in perfect condition.

China Custom Customized agricultural Factory Supply Agriculture Tractor Parts Automobile Transmission Shaft Transmission Rear Drive Shaft near me shop

Situation: New

Warranty: 3 months

Applicable Industries: Production Plant

Excess weight (KG): 3 KG

Showroom Location: None

Video outgoing-inspection: Not Accessible

Machinery Test Report: Not Available

Advertising and marketing Variety: Ordinary Product

Kind: Shafts

Merchandise Title: Transmission shaft

Material: Metal

Color: Yellow

Function: Agricultural equipment

Keywords: push shafts

Design: Customized travel shafts

Service: 24 Several hours On the web

Item Identify: propeller shafts

Purpose: shafts travel

Merchandise Type: tractor pto shaft

Packaging Details: eighty-one hundred twenty cm

Port: Main ZheJiang /HangZhou

TypeShaftsProduct NameTransmission shaftMaterialSteelFeatureAgricultural machinery Certifications Packaging And Logistics Q1: Are you investing company or manufacturing facility? A1:We are drivesahft manufacturing unit. Q2: Can you make or modify the propeller shaft we want? A2:Of course, For CZPT Truck Gearbox Transmission Components 2nd equipment 4357196 4302670 4357195 435715 3315743 4304057 4304063 Samples for growth are warmly welcomed. We have abundant experience in developing and modifying the shafts.Q3:What is Moq for every single products.If we have in inventory?A3:sample check and sample orders could be accepted.Typically MOQ is 1pcs.This fall: How can l be confident the areas in shape my car?A4:Make sure you guidance the elements no to our income, Industrial Heavy Responsibility cable rollers bearings Straight Line Bridge Cable pulling Roller and affirm with them.Just ship theimages of the elements to our income or ask our product sales to deliver you impression to affirm.Q5:What other support can you supply?A5:OEM services, 10kV Epoxy Resin Insulated transformer Wall bushing sleeve for Switchgear 12KV we are often warmly welcome client to deliver us sampleto produce a new item line.

Push shaft sort

The driveshaft transfers torque from the engine to the wheels and is dependable for the easy working of the motor vehicle. Its design and style experienced to compensate for variations in length and angle. It should also make certain best synchronization amongst its joints. The generate shaft ought to be manufactured of higher-quality supplies to obtain the best equilibrium of stiffness and elasticity. There are three primary varieties of travel shafts. These consist of: conclude yokes, tube yokes and tapered shafts.

tube yoke

Tube yokes are shaft assemblies that use metallic components as the main structural component. The yoke involves a uniform, considerably uniform wall thickness, a first end and an axially extending second end. The very first diameter of the travel shaft is better than the second diameter, and the yoke more contains a pair of opposing lugs extending from the 2nd stop. These lugs have holes at the finishes for attaching the axle to the motor vehicle.

By retrofitting the driveshaft tube conclude into a tube fork with seat. This valve seat transmits torque to the driveshaft tube. The fillet weld 28 boosts the torque transfer capacity of the tube yoke. The yoke is normally manufactured of aluminum alloy or metallic content. It is also utilized to connect the generate shaft to the yoke. A variety of patterns are attainable.

The QU40866 tube yoke is utilized with an external snap ring variety universal joint. It has a cup diameter of 1-3/16″ and an all round width of 4½”. U-bolt kits are yet another selection. It has threaded legs and locks to aid secure the yoke to the push shaft. Some overall performance automobiles and off-road cars use U-bolts. Yokes must be machined to accept U-bolts, and U-bolt kits are frequently the chosen accent.

The finish yoke is the mechanical element that connects the push shaft to the stub shaft. These yokes are usually developed for distinct drivetrain factors and can be tailored to your needs. Pat’s drivetrain offers OEM replacement and customized flanged yokes.

If your tractor utilizes PTO factors, the cross and bearing kit is the excellent resource to make the connection. Moreover, cross and bearing kits help you match the proper yoke to the shaft. When choosing a yoke, be confident to measure the outside the house diameter of the U-joint cap and the inside diameter of the yoke ears. Soon after taking the measurements, consult the cross and bearing identification drawings to make positive they match.

Although tube yokes are typically straightforward to replace, the very best benefits occur from a qualified equipment shop. Focused driveshaft professionals can assemble and stability finished driveshafts. If you are uncertain of a certain facet, remember to refer to the TM3000 Driveshaft and Cardan Joint Support Handbook for far more info. You can also consult an excerpt from the TSB3510 handbook for info on angle, vibration and runout.

The sliding fork is yet another essential component of the travel shaft. It can bend over rough terrain, permitting the U-joint to maintain spinning in more durable circumstances. If the slip yoke fails, you will not be able to generate and will clang. You want to replace it as quickly as attainable to stay away from any dangerous driving problems. So if you recognize any dings, be certain to check the yoke.

If you detect any vibrations, the drivetrain may want adjustment. It really is a simple approach. First, rotate the driveshaft till you find the right alignment among the tube yoke and the sliding yoke of the rear differential. If there is no visible vibration, you can wait around for a although to solve the difficulty. Preserve in thoughts that it may be hassle-free to postpone repairs briefly, but it might trigger bigger difficulties later on.

conclude yoke

If your driveshaft needs a new conclude yoke, CZPT has numerous drivetrain possibilities. Our automotive finish yoke inventory consists of keyed and non-keyed choices. If you want tapered or straight holes, we can also make them for you.

A U-bolt is an industrial fastener that has U-shaped threads on its legs. They are usually utilized to sign up for two heads back again to back again. These are handy options to assist preserve drivetrain parts in place when driving more than tough terrain, and are generally suitable with a selection of models. U-bolts require a specifically machined yoke to accept them, so be confident to buy the right measurement.

The sliding fork assists transfer power from the transfer case to the driveshaft. They slide in and out of the transfer circumstance, enabling the u-joint to rotate. Sliding yokes or “slips” can be bought independently. Regardless of whether you require a new 1 or just a number of components to improve your driveshaft, 4 CZPT Components will have the components you need to have to restore your vehicle.

The end yoke is a essential portion of the travel shaft. It connects the travel practice and the mating flange. They are also employed in auxiliary electricity products. CZPT’s drivetrains are stocked with a selection of flanged yokes for OEM purposes and personalized builds. You can also discover flanged yokes for consistent velocity joints in our in depth stock. If you will not want to modify your existing drivetrain, we can even make a personalized yoke for you.